The Protolis guide to compression molding

In this guide, you will find comprehensive instructions for Compression Molding, a widely used method for crafting precise, high-quality rubber components.

Method Type

Jump to current chapter

How does compression molding work?

As we saw, compression molding is a straightforward process in which pre-measured rubber material is placed into a heated mold, compressed under pressure, and then cured into its final shape. Its simplicity makes it highly versatile: ideal for producing durable components in small to medium volumes, as well as for rapid prototyping to validate designs before scaling to mass production.

Discover the possibilities of rapid prototyping with Protolis: Rapid prototyping

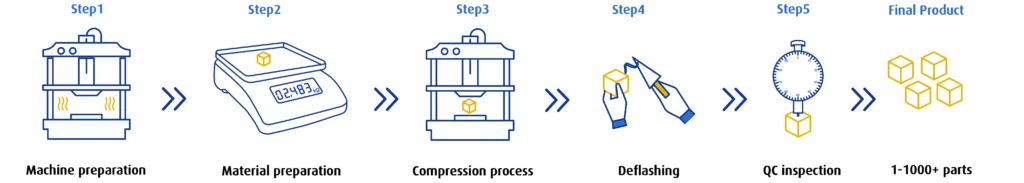

• The compression molding process

The compression molding process relies on five critical steps that must be carefully followed to ensure consistent product quality. From machine and material preparation to compression, deflashing, and inspection, each stage helps prevent defects and ensures the final parts meet required specifications. Precision in these steps is essential for reliable, high-quality results.

- Machine preparation: The process starts with the compression molding machine, where the mold is preheated to optimize the curing of the rubber. The temperature settings and compression time are crucial as they affect the quality and characteristics of the final product.

- Material preparation: Rubber preforms are precisely weighed and checked before being placed into the mold. This is important to prevent defects such as weak parts resulting from underfilling or excess material (flash) resulting from overfilling.

- Compression process: In this central phase, the preform is placed into the heated mold, which is then closed to compress the material. Heat and pressure are applied, causing the thermoset to conform to the shape of the mold. During this stage, a degassing step expels any trapped air to prevent voids or weak spots in the final product.

- Deflashing: After the thermoset material has cured, the mold is opened, and the excess material is trimmed away to ensure the final product meets precise dimensional requirements.

- QC inspection and final product: The last step involves a thorough inspection of each part to ensure it meets the required specifications. Parts that pass the inspection are then packaged and prepared for dispatch.

This method is valued for its simplicity and cost-effectiveness. It is especially suitable for producing larger volumes of standard products. However, by adjusting the mold design and processing conditions, it can also be adapted for smaller batches or more customized specifications.

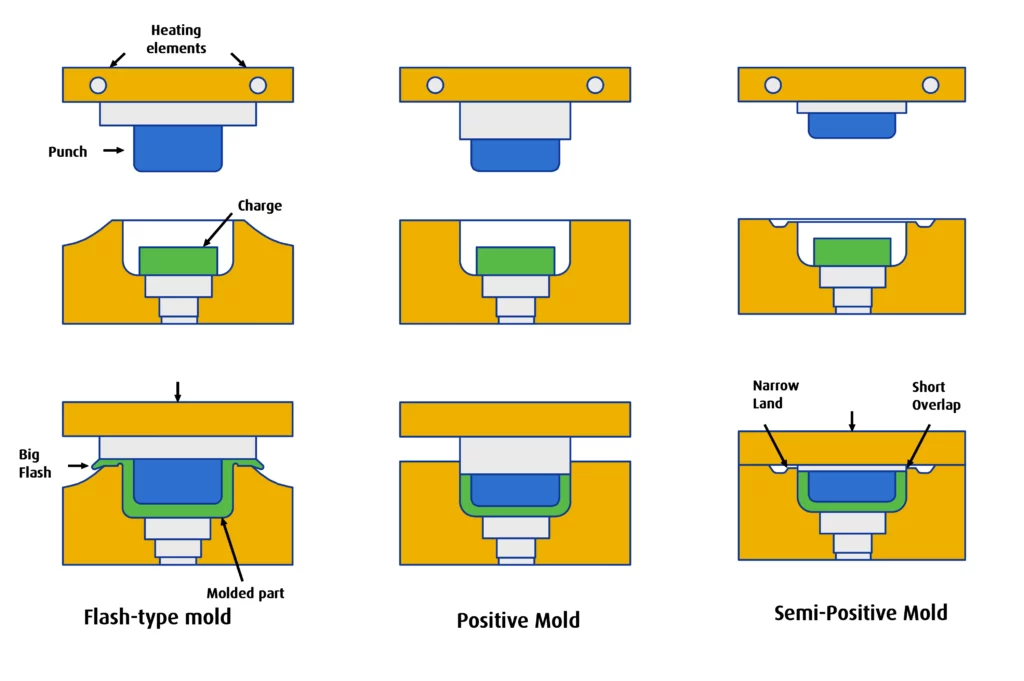

• Types of rubber compression molds

While the overall process remains consistent, there are three main types of molds commonly used in the industry: flash, positive, and semi-positive molds. Each has its advantages depending on part design, production volume, and quality expectations.

- Flash-type mold: Flash-type molds are the most commonly used for compression molding. The mold plates close with a small clearance, allowing excess material to escape and form flash at the parting line, which is removed after molding. Because they are simple to manufacture and tolerant of variations in material volume, flash molds are ideal for prototyping and small-batch production. They enable quick iterations, lower tooling costs, and a fast turnaround without compromising functional performance.

- Positive Mold: Positive molds are built for precision. The cavity is fully enclosed, providing no room for flash. The rubber charge must be precisely measured and positioned. This approach yields clean, consistent parts with minimal post-processing requirements. But, it is less forgiving, slower to set up, and pricier to tool. Positive molds are generally reserved for applications requiring high dimensional stability or cosmetic perfection, typically at later stages of development.

- Semi-Positive Mold: Semi-positive molds offer a compromise. They allow limited, controlled flash to escape into overflow grooves, making them more flexible than positive molds, while still delivering a cleaner finish than flash molds. They are a solid choice for medium-volume production when a cleaner part is needed, but without the cost or rigidity of fully enclosed tooling.

• Key equipment for compression molding

The successful execution of compression molding depends not only on process control but on the use of specialized machinery designed to deliver precision, consistency, and efficiency. Each piece of equipment within a molding facility contributes to production reliability and the quality of the final parts.

Compression molding relies on several types of machinery to ensure the efficient production of rubber parts. Core equipment includes:

- Large tonnage presses: These presses vary widely, with capacities ranging from 50 to 1,500 tons, accommodating a range of molded product sizes and complexities.

- Heating chamber: A dedicated chamber or oven heats the material to the required temperature for molding.

- Mold: The mold comprises two halves—upper and lower—that are precision-machined to form the desired product shape.

- Automation systems: These include conveyor systems, hoppers, robotic arms, temperature control units, and mechanical ejection systems, all designed to streamline the molding process.

- Air: Compressed air systems are employed for cleaning the mold cavities and part surfaces, ensuring they are free from debris.

- Heating: Long, slender cylindrical electric resistors are used to maintain a consistent heating temperature.

Together, these tools play a vital role in the setup and operation of a compression molding facility, enhancing both productivity and product quality.

Continue your exploration of compression molding in other chapters:

Benefits and limitations of compression molding

When to choose compression molding for prototypes and low volume manufacturing?

Comparison with other technologies