The Protolis guide to compression molding

In this guide, you will find comprehensive instructions for Compression Molding, a widely used method for crafting precise, high-quality rubber components.

Method Type

Jump to current chapter

What is compression molding?

• Introduction to compression molding

Compression molding is a manufacturing process in which a pre-shaped silicone or rubber material, called a preform, is placed into a heated mold cavity. The mold is then closed, and the combined application of heat and pressure causes the material to flow, ensuring complete cavity filling while eliminating air voids. Heat simultaneously initiates the curing reaction, while pressure maintains dimensional accuracy and prevents defects from occurring. The thermoset material must then be allowed sufficient time to cure fully, developing the required mechanical strength, durability, and dimensional stability. This technique is widely employed across industries to produce high-quality precision components, particularly those with low Shore hardness.

• The history of rubber compression molding

Rubber compression molding is the earliest known technique in rubber molding, with origins dating back to the 1890s. The method was pioneered by Harvey Firestone, who employed it in the production of the first consumer rubber products. Since its introduction, the core process principles have remained largely consistent. Owing to its simplicity and effectiveness, rubber compression molding has long been regarded as a reliable method for manufacturing a vast range of rubber components. This foundational method also played a pivotal role in enabling the development of more advanced molding techniques, which are widely used in modern production.

• Key terms in compression molding

Compression molding is a common manufacturing process for shaping thermoset materials such as rubber and silicone under heat and pressure. To better understand the process and its quality requirements, it is vital to be familiar with certain technical terms used in the industry. The following are key concepts that describe essential steps, measurements, and outcomes in compression molding:

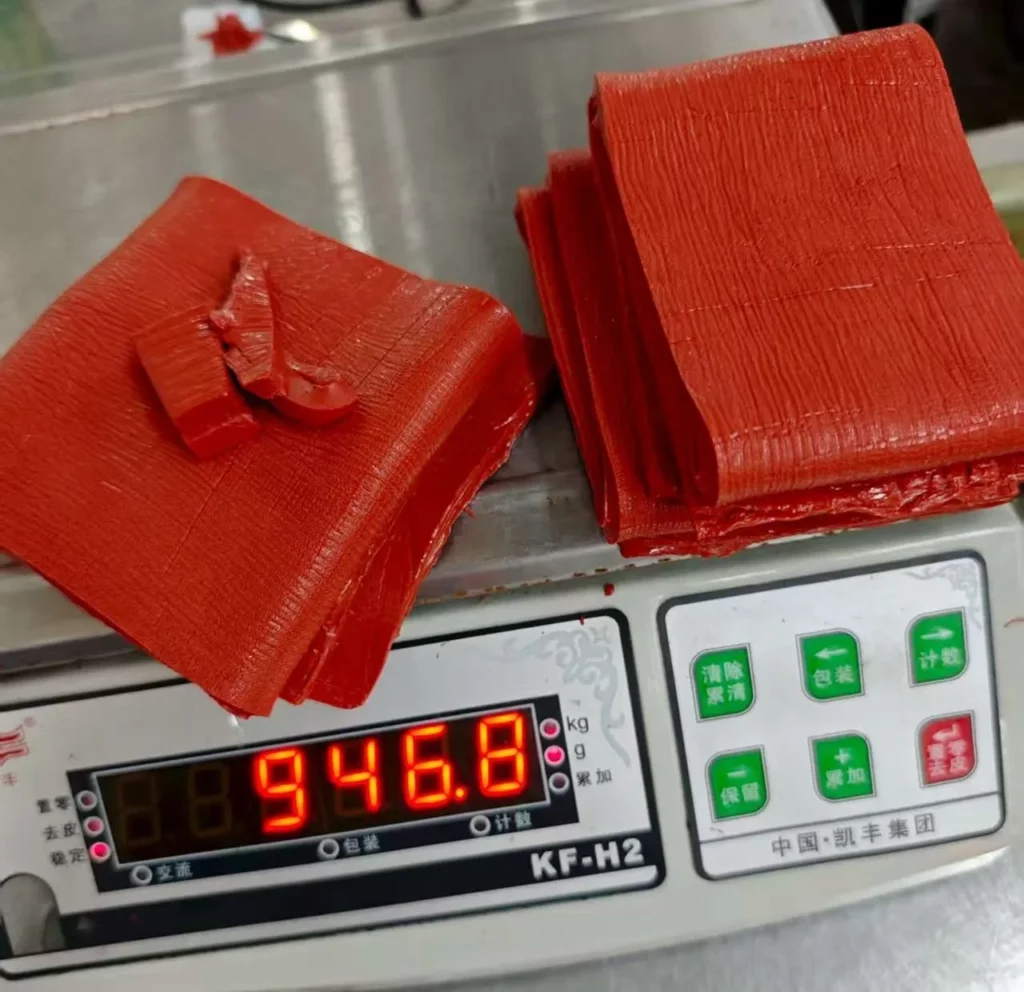

Preform: A precisely measured and often shaped amount of raw rubber or silicone placed into the mold.

Curing (Vulcanization): The chemical process (heat + pressure) that cross‑links polymer chains and hardens thermoset materials.

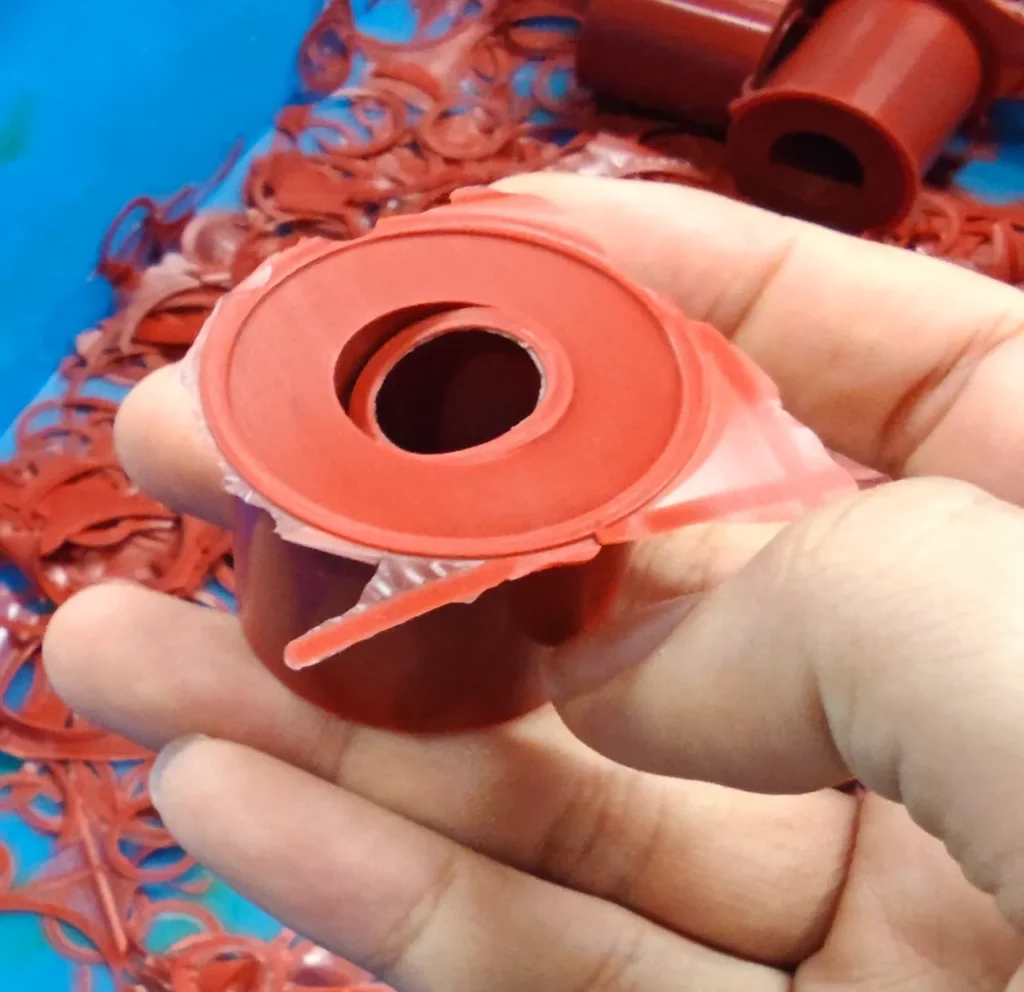

Flash: Excess material that escapes the mold cavity during compression.

Degassing: The release of trapped air from the material during molding to prevent voids.

Durometer (Shore Hardness): A scale (e.g., Shore A, D) used to measure the hardness of elastomers.

Deflashing: The post-molding process of trimming away flash to achieve precise part dimensions.

Continue your exploration of compression molding in other chapters:

How does compression molding work?

Benefits and limitations of compression molding

When to choose compression molding for prototypes and low volume manufacturing?

Comparison with other technologies