Acrylic, also known as polymethyl methacrylate (PMMA), is prized for its crystal-clear transparency, impact resistance, and versatility. However, after cutting, milling, or machining, edges often appear frosted or dull. Polishing restores the smooth, glass-like clarity that makes acrylic so visually appealing.

The go-to polishing method depends on the desired quality, the part’s geometry, and cost considerations. Let us examine the four most common techniques offered by Protolis, ranging from quick finishing to ultra-precise, high-end results.

1. Diamond polishing: premium clarity for flat and angled edges

Diamond polishing delivers exceptional clarity and a flawless, consistent finish, making it the preferred choice for premium display pieces, optical components, and high-spec parts.

- Process: Performed on semi-automatic machines equipped with precision diamond tools.

- Best for: Flat or angled edges.

- Advantages: Ultra-clear, highly consistent, professional-grade results.

- Limitations: Not suitable for curved surfaces.

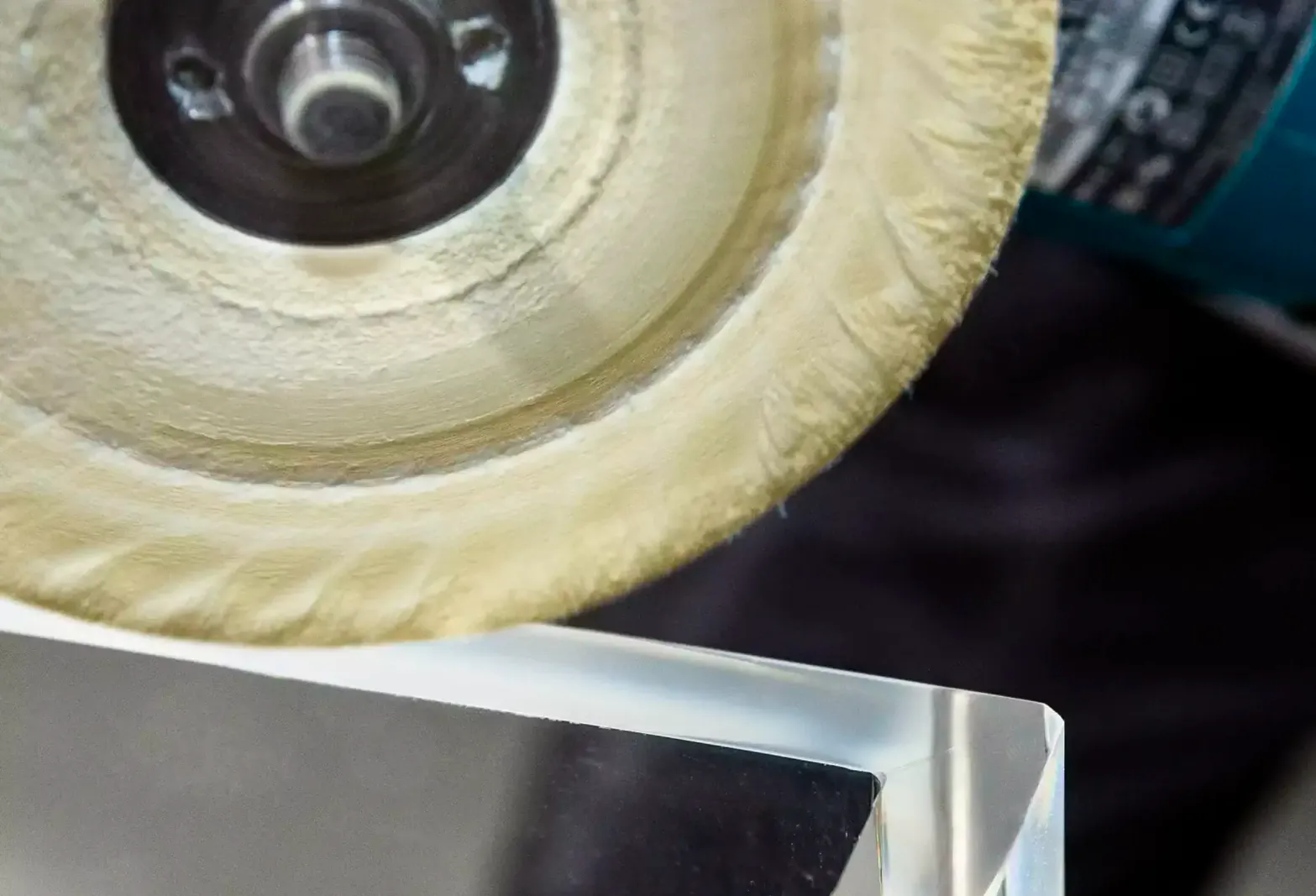

2. Cloth wheel polishing: versatile and high-quality finish

Cloth wheel polishing utilizes a rotating cloth wheel combined with polishing compounds such as aluminum oxide to remove scratches, smooth surfaces, and achieve a mirror-like finish.

- Process: The compound is applied to the buffing wheel or directly to the PMMA surface. The part is then polished in smooth, even motions to avoid overheating or distortion

- Best for: Both flat and curved surfaces, including complex shapes

- Advantages: Can achieve near-mirror transparency without vapor polishing

- Limitations: Labor-intensive and slower than automated methods

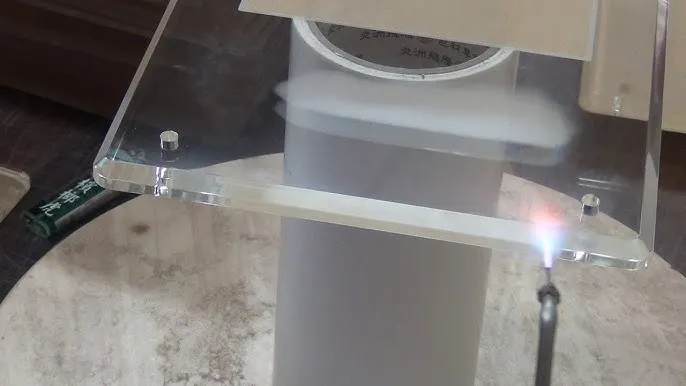

3. Flame polishing: fast and economical

Flame polishing uses a high-temperature flame (often from an alcohol-fueled torch) to melt and reflow the acrylic’s surface, restoring clarity quickly.

- Process: The flame passes over the edge, smoothing and clarifying it in seconds

- Best for: Straight edges where minor imperfections are acceptable

- Advantages: Very fast and inexpensive

- Limitations: Finish can be inconsistent; precision is lower than that of other methods

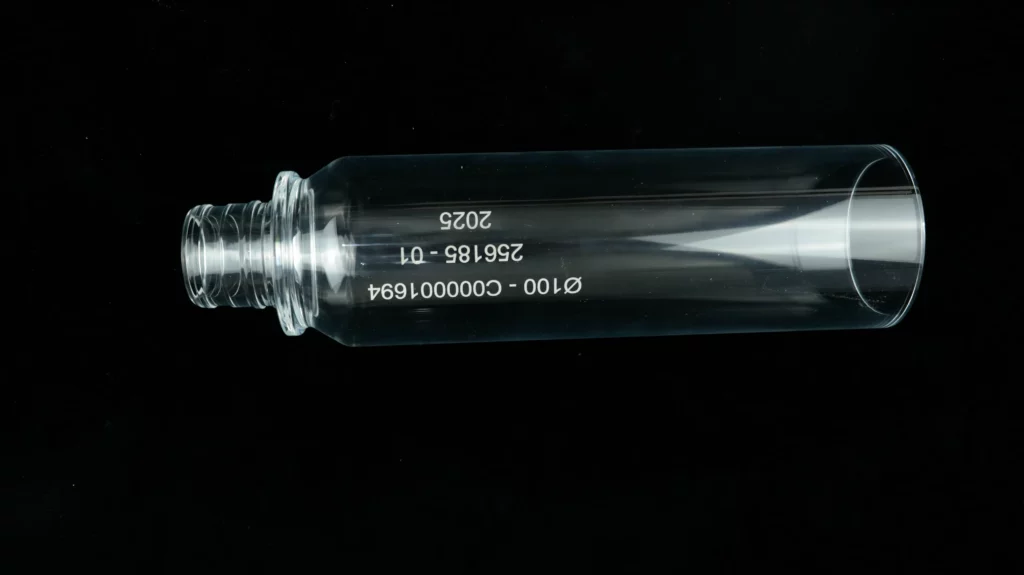

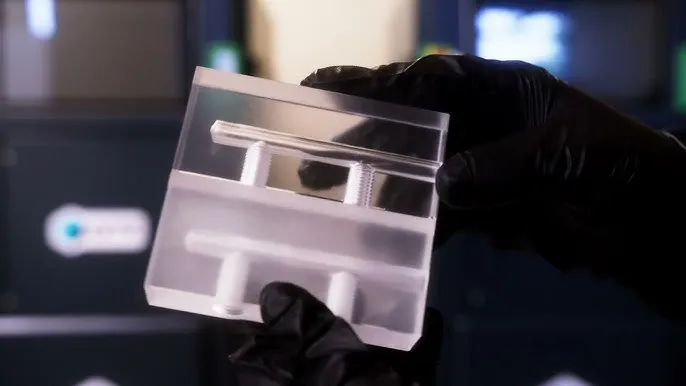

4. Vapor polishing: the ultimate clarity for intricate details

Vapor polishing is a specialized chemical process that uses solvent vapors (e.g., dichloromethane, THF, chloroform) to smooth the surface at a microscopic level.

- Process: First, the part is pre-polished manually or mechanically to remove larger imperfections. Then, solvent vapor is applied, gently melting the outer layer and producing an optically transparent surface

- Best for: Small, intricate, or internal features, such as threads, channels, and inspection windows, where mechanical polishing is difficult

- Advantages: Exceptional for hard-to-reach areas and for improving overall transparency

- Limitations: Requires skilled handling and proper solvent selection for each plastic type

Choosing the Right Method

In many projects, we will employ a combination of these techniques, utilizing diamond polishing for primary edges, buff polishing for curved surfaces, and vapor polishing for complex internal features to achieve the optimal balance of speed, cost-effectiveness, and visual excellence. With Protolis’ expertise and advanced capabilities, these methods are applied with precision to deliver finishes that meet functional requirements and enhance aesthetic appeal. This level of quality is particularly valuable in marketing and presentation contexts, where the appearance of a product can significantly influence perception, customer engagement, and ultimately, commercial success. Let’s start your project with us and bring your vision to life.