| Product | Bodywork prototype for Peugeot motorcycle |

| Technology | CNC, Vacuum casting |

| Material | ABS, PA, PP, PU ABS |

| Finish | Technical polishing |

| Timeline | 46 days |

| Quantity | 45pcs for one set |

About our client

Peugeot Motocycles is a historic French manufacturer with over a century of innovation in two-wheel mobility. Renowned for its blend of engineering precision and elegant design, the company develops a full range of scooters and motorcycles that combine performance, comfort, and distinctive European style. With a strong presence in international markets, Peugeot Motocycles continues to push the boundaries of urban mobility through advanced technology and refined craftsmanship.

At Protolis, we take pride in transforming ambitious concepts into tangible, high-performance prototypes. This project for Peugeot is a clear example of how our team supports customers through every technical challenge — from completing data to complex geometries and demanding surface finishes.

Key challenges and solutions

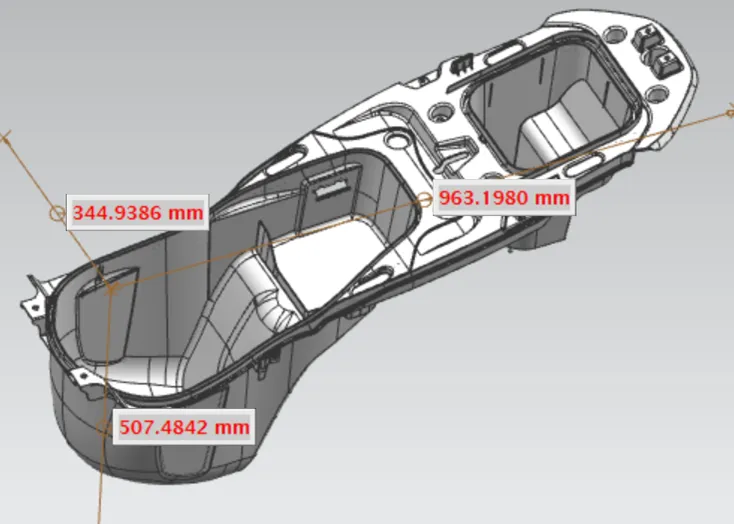

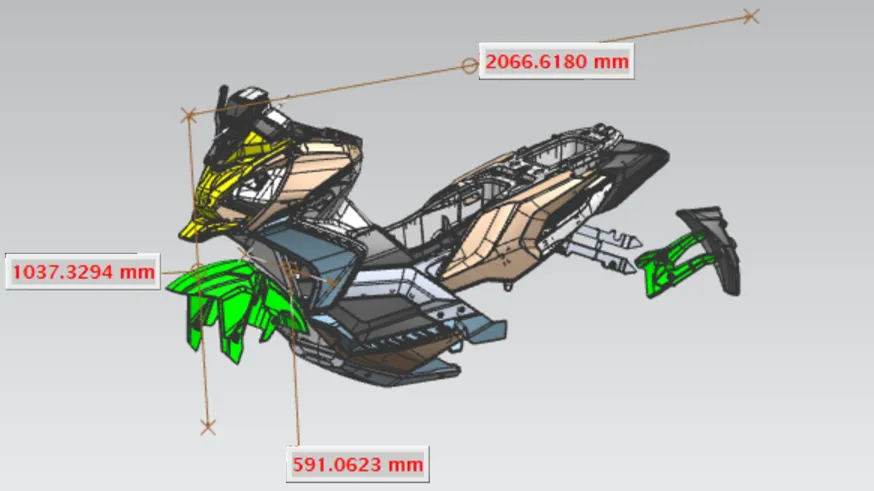

The new Peugeot scooter is a high-performance racing motorcycle recognized for its sharp, angular design and streamlined aesthetic. The scope of this project encompassed the fabrication of a complete plastic bodywork prototype, comprising 45 individual components that form the vehicle’s full external shell.

1. Material and process diversity

Meeting both structural and visual standards required a careful combination of four distinct materials and two manufacturing processes: CNC machining and vacuum casting. This deliberate mix was not arbitrary—it allowed us to fine-tune the balance between rigidity, flexibility, and surface finish. In most cases, achieving that equilibrium in a prototype of this scale demands iterative adjustments, but with our accumulated experience, we were able to define stable parameters early in development.

Protolis’s technical team remained closely involved throughout, providing guidance on optimal processing methods and material behavior during forming and finishing stages. This proactive support helped maintain dimensional accuracy and visual consistency across all 45 parts.

2. Engineering without complete drawings

The client supplied only the designs for the plastic components. Due to confidentiality constraints, no full assembly drawings or metal-part schematics were made available. As a result, our engineering team had to independently reconstruct and analyze the assembly relationship.

Through careful study of potential interference zones and connection interfaces, we identified risks of misalignment and proposed corrective measures before machining began. One will generally find that such early engineering insight saves considerable time downstream—and in this case, it was key to ensuring that the bodywork assembled flawlessly once delivered.

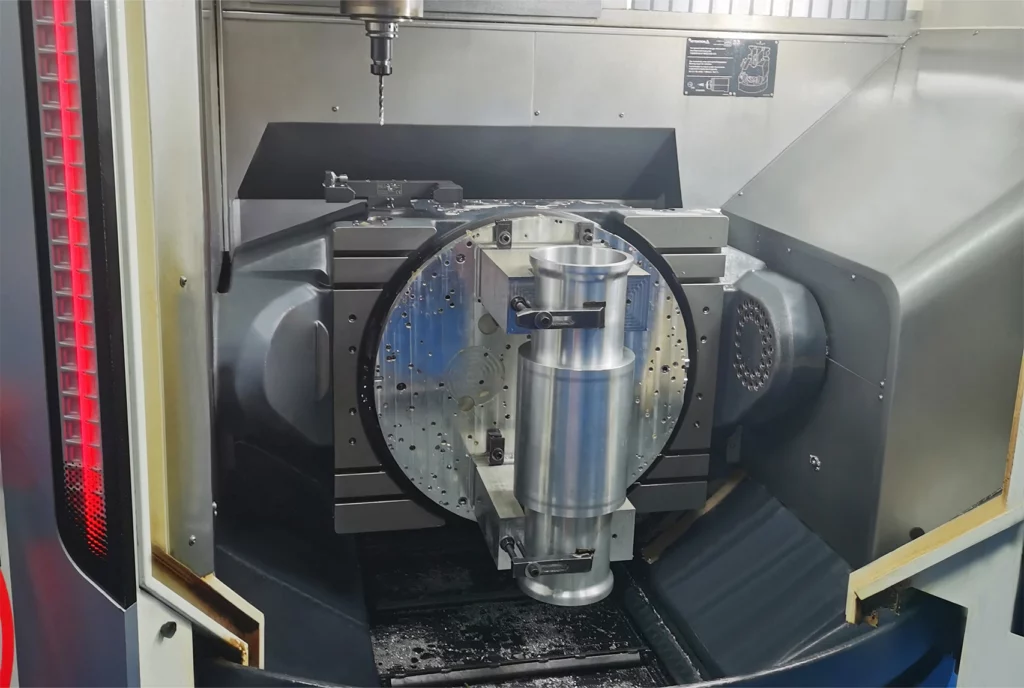

3. Complex geometry and precision machining

Many of the body panels featured intricate geometries with deep undercuts that could not be produced through standard 5-axis CNC machining. To address these challenges, our engineers developed a multi-part bonded construction strategy.

This method demands both, deep technical understanding and hands-on familiarity with mechanical joining. The goal was not only to reproduce the designer’s intent but also to ensure that each bonded piece maintained strength and visual continuity. Protolis’ engineering support was instrumental here—providing structural performance through practical testing and dimensional review.

Learn more about polishing:

Four main types of acrylic (PMMA) polishing processes in Protolis

4. Surface treatment and finishing

Once the parts were machined and bonded, all surfaces were prepared to a paint-ready standard. Our technicians meticulously removed tool marks and joint traces through progressive manual polishing, aided by a custom-designed jig to maintain uniform pressure and geometry.

Surface preparation may sound routine, but on a prototype of this complexity, the difference between “good” and “ready for paint” can be measured in hours of patient work. The result was a surface that required no corrective rework before painting, achieving a flawless, high-end finish that reflected the precision of the underlying engineering.

5. Large-scale assembly and on-site success

The completed prototype measured roughly two meters in length and one meter in height, with the largest single part reaching one meter by fifty centimeters. Given this scale, assembly tolerances were exceptionally tight. Thanks to our methodical approach and the technical guidance provided by the Protolis support team, the whole assembly was completed successfully on the first attempt at the client’s facility.

Results

Such an outcome doesn’t happen by chance—it reflects detailed planning, disciplined engineering control, and continuous coordination between our workshop and the client’s team. Over the years, Protolis has gained extensive experience in producing complex bodywork prototypes for leading automotive and motorcycle brands, mastering the balance between technical precision and design fidelity.

Explore more of our bodywork and frame prototype projects here:

A racing concept car bodywork prototype for one of the world’s premier auto shows

Our goal is always the same: to make complex prototype production straightforward and reliable for our clients. Whether you are developing a one-off concept or a full-scale pre-production prototype, the Protolis team is ready to provide the same level of precision, flexibility, and hands-on technical care that make projects like this possible. Contact us now!