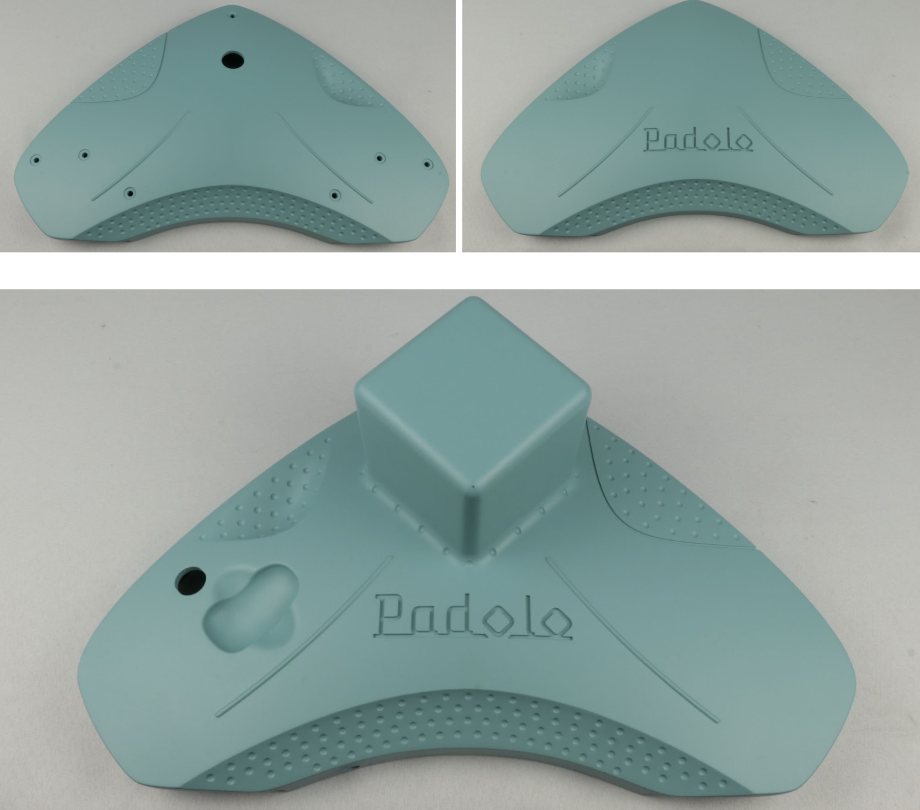

| Product | Mobile motorized pool cover reel |

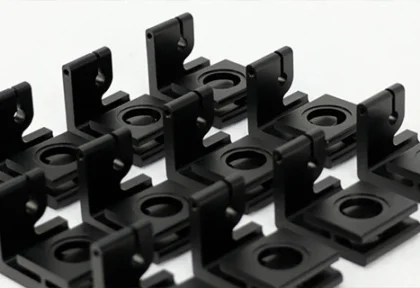

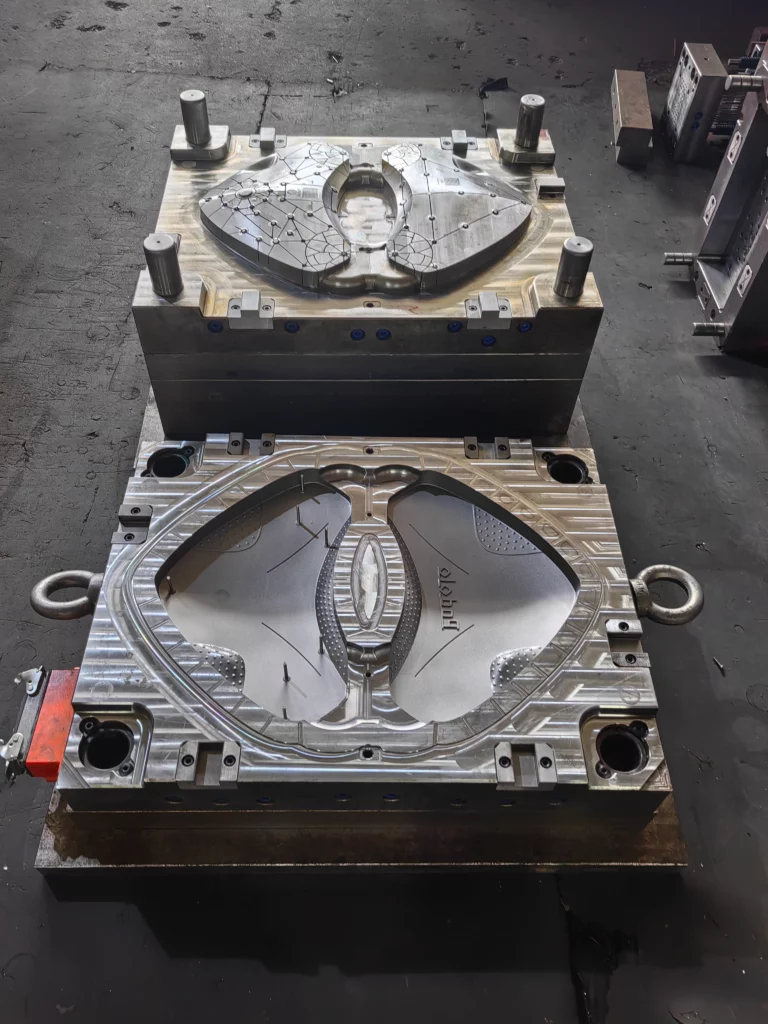

| Technology | CNC, Injection |

| Material | ASA, stainless steel, aluminum |

| Finish | Technical polishing, anodization, painting, sandblasting |

| Timeline | 46 days for prototypes, 60 days for the first batch |

| Quantity | 500 sets |

About our client

Our client is a French brand dedicated to improving the everyday experience of pool owners through practical, user-driven innovation, specializing in automated safety cover solutions. Their goal has remained straightforward from the start: transform a repetitive, heavy task into something quick, reliable, and effortless.

Key challenges and solutions

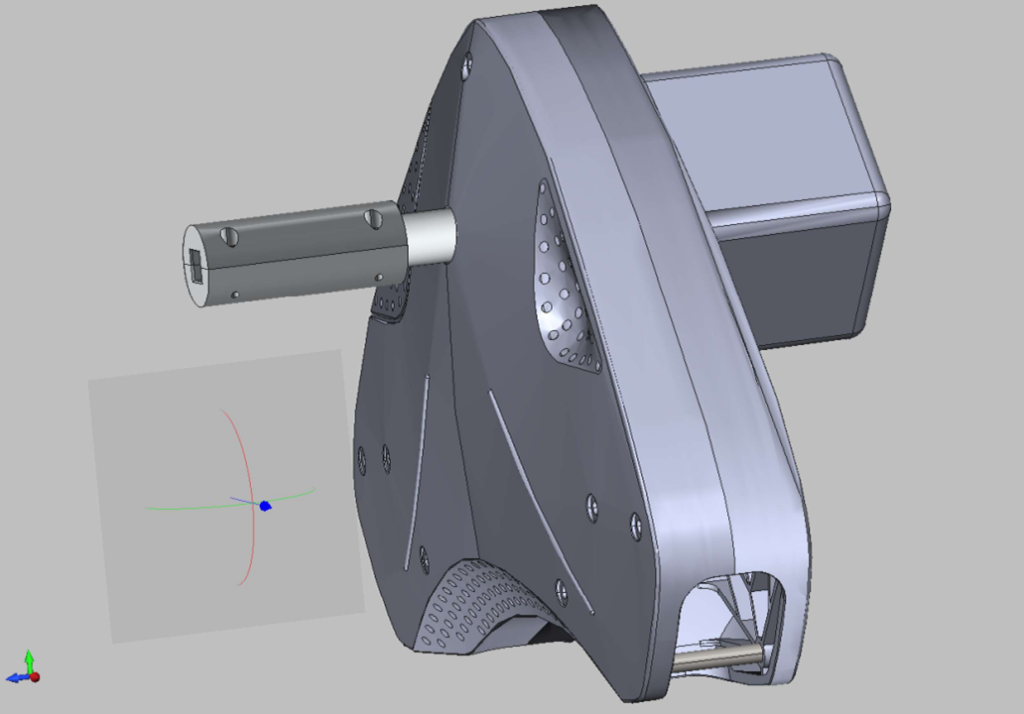

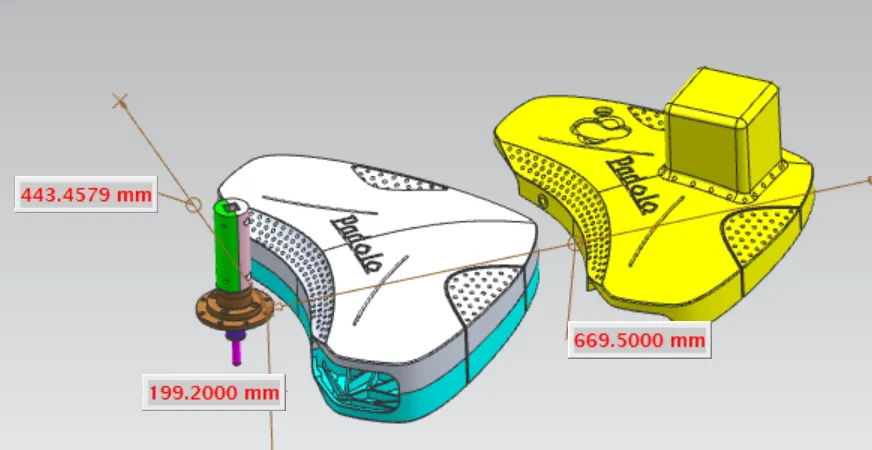

This project focused on developing a compact, mobile motorized pool cover reel. While the product looks simple from the outside, its internal structure requires precise engineering and controlled production. Protolis stepped in early, delivering quick prototypes to confirm functionality before making larger investments. From there, we supported the customer in transitioning to small-batch production so they could test the product in real market conditions and refine it with minimal risk. This approach helped reduce upfront costs and enabled a faster, more confident go-to-market. With steady technical support at each stage, Protolis helped turn a promising concept into a commercially viable solution.

1. Managing complexity across all project stages

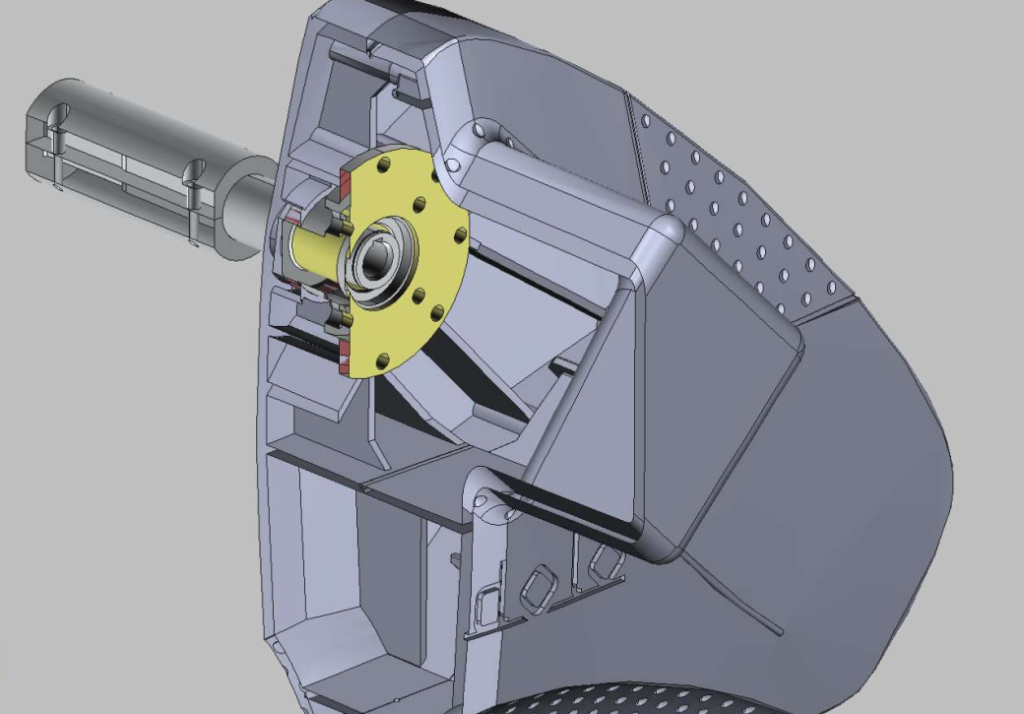

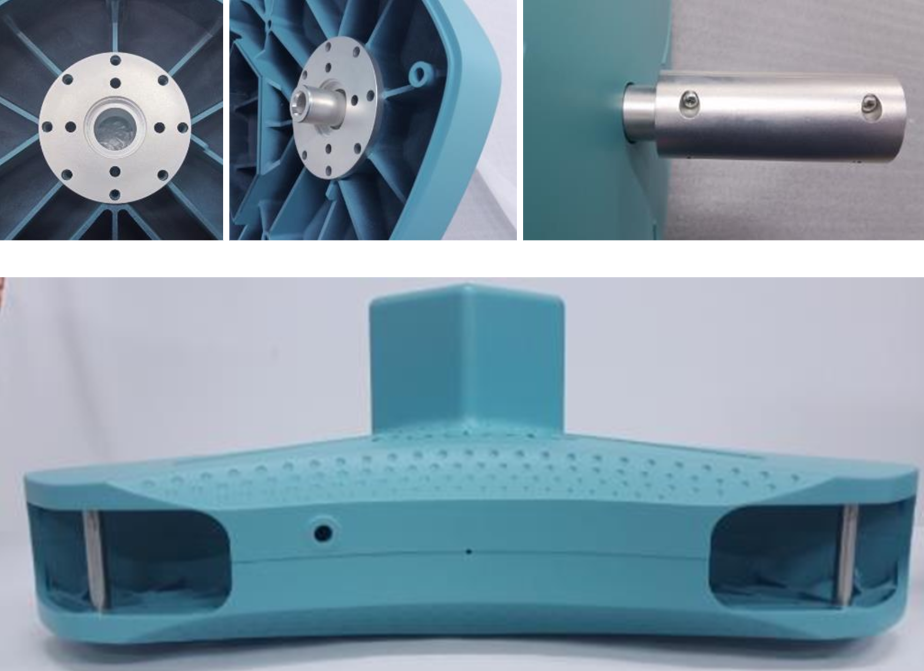

The roller system contains over twenty components made of plastic, aluminum, and stainless steel. Integrating these parts into a single, reliable assembly was one of the main technical hurdles. Protolis guided the customer through each phase—from early design adjustments for prototypes to stable small-series production.

Advantages of working with Protolis: Our small-batch production capabilities allowed the customer to validate the product in real-market conditions before committing to large-scale investments. This approach reduced financial risk and enabled the customer to refine the design based on early user feedback.

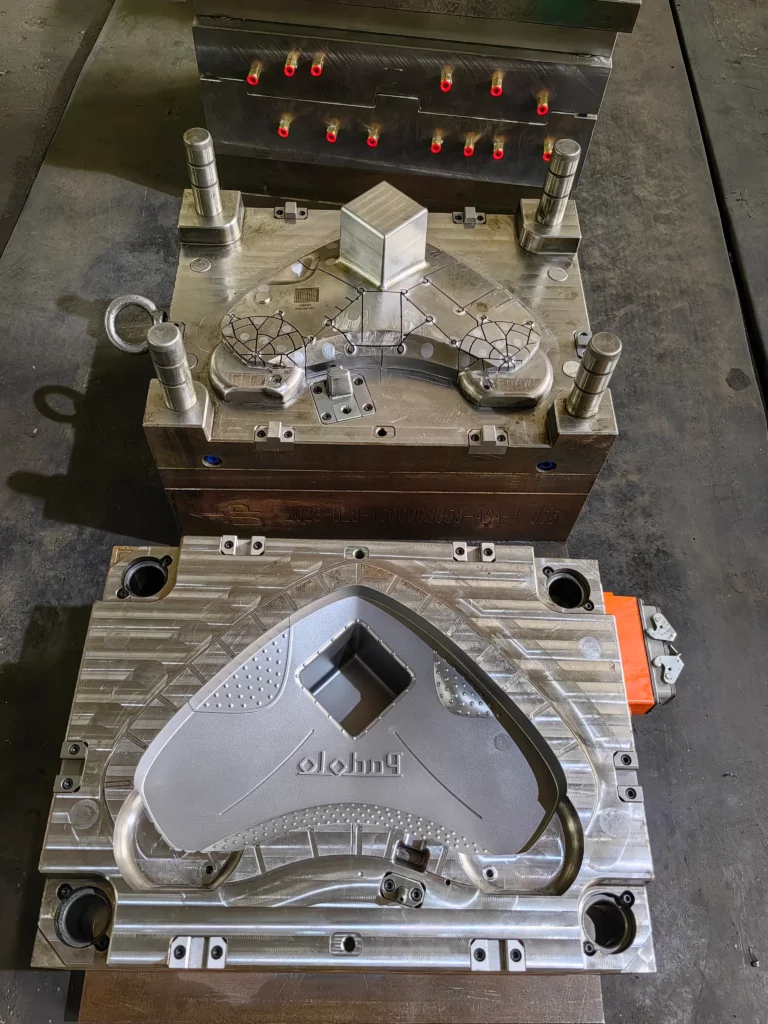

2. Design optimization and DFM

We carried out detailed Design for Manufacturing optimization covering internal wall thicknesses, thread positions, assembly feasibility, and visual detailing. Getting these fundamentals right tends to eliminate many downstream corrections, and here it contributed significantly to a smoother transition from prototype to production.

Advantages of working with Protolis:

Because we handle engineering refinement and small-batch manufacturing in-house, design changes can be tested quickly, helping customers accelerate their go-to-market timeline without sacrificing precision.

3. High-fidelity prototyping

The prototype phase required mixed manufacturing methods:

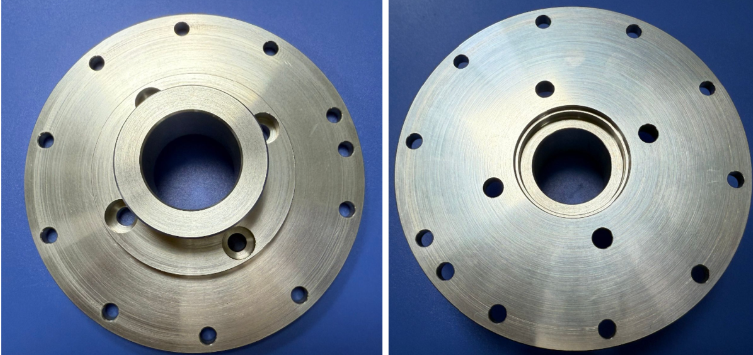

- Metal parts, CNC-machined to tight tolerances

- Aluminium components, sandblasted and anodized to match stainless steel visually

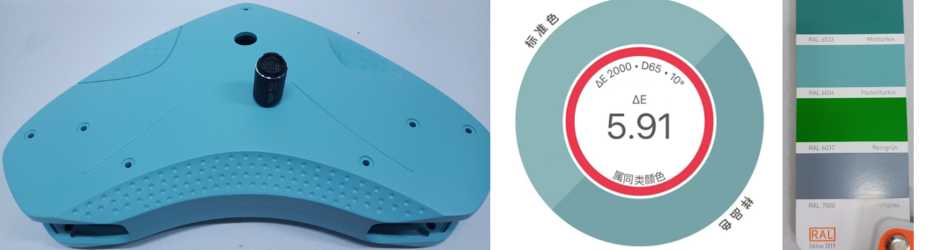

CNC plastic parts with strict color consistency

Protolis remained closely involved to ensure that the mechanical fit and visual alignment held together across materials.

Advantages of working with Protolis:

Our ability to deliver high-quality prototypes in small runs gives customers a practical way to test market response with production-grade samples, rather than rough models, usually leading to more reliable feedback and more transparent decision-making.

4. Assembly challenges and structural requirements

With two large structural plastic shells, multiple aluminum and stainless components, a motor system, supporting feet, and numerous threaded interfaces, the assembly process demanded careful coordination. Several assembly trials were required to determine optimal threading specs and ensure a consistent fit.

The product also had to withstand a 200 kg load, requiring reinforcement of specific areas and targeted mechanical testing.

Protolis oversaw each of these steps to ensure that engineering intent matched real-world assembly conditions—something that is rarely straightforward on the first iteration.

5. Testing and quality control

All samples underwent functional testing, assembly testing, visual inspection, and mechanical evaluation. These checks prevented drift in both performance and aesthetics—especially important when working with multiple surface treatments and mixed materials and technologies.

6. Post-launch refinements

Following the initial market launch, the customer requested cost-controlled improvements to simplify assembly and improve the assembling of the injected parts. Protolis modified the existing injection mold, particularly the parting line between the components, to enhance visual alignment between the upper and lower housings. These changes significantly improved the perceived quality without requiring a complete mold replacement.

Advantages of working with Protolis:

Our approach keeps improvement loops affordable. Customers can refine their products with modest investments instead of facing major tooling changes early in the product’s life.

7. Establishing stable series production

After validation, we established consistent processes for manufacturing, surface finishing, color control, and assembly to ensure reliable output as the project transitioned from pilot batches into ongoing production.

Final result and strategic benefits

The finished automatic roller system is durable, visually cohesive, and ready for sustained commercial rollout. By working with Protolis, the customer gained:

- Small-batch production for controlled early distribution

- Reduced up-front investment by avoiding premature large-scale tooling

- The ability to conduct real-world market testing with production-quality parts

- A faster and more confident go-to-market path, supported by responsive engineering and flexible production cycles

Through steady, hands-on technical support, Protolis helped transform a complex assembly into a reliable product, ready for the market, with minimized risk and a streamlined development path.

If you are preparing a new hardware project or exploring small-batch production for early market testing, contact us now!