| Product | rapid microbiological testing equipment enclosures |

| Technology | CNC |

| Material | ABS, stainless steel |

| Finish | Painting |

| Timeline | 20 days |

| Quantity | 15 sets |

About our client

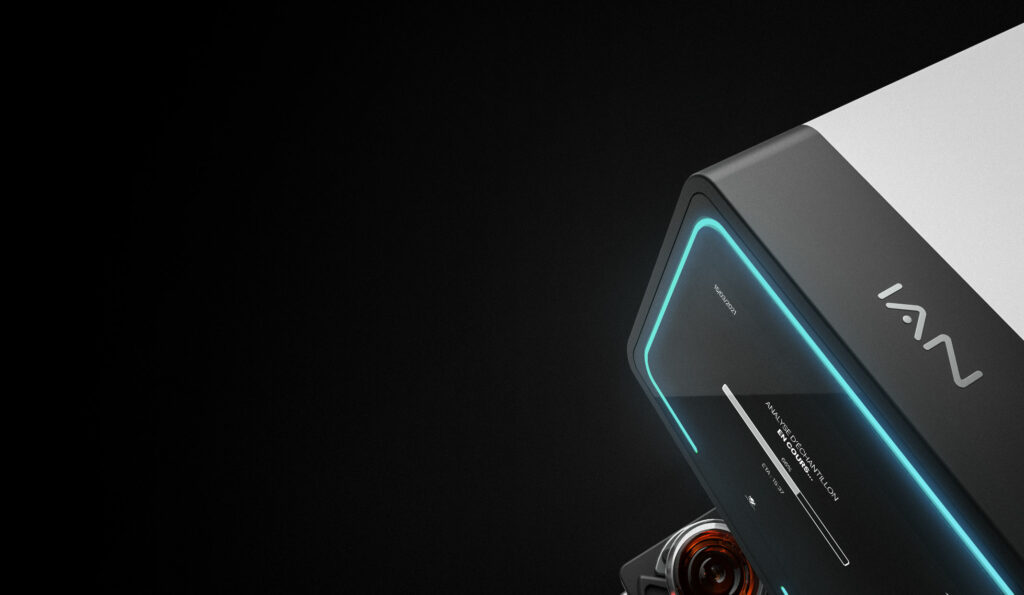

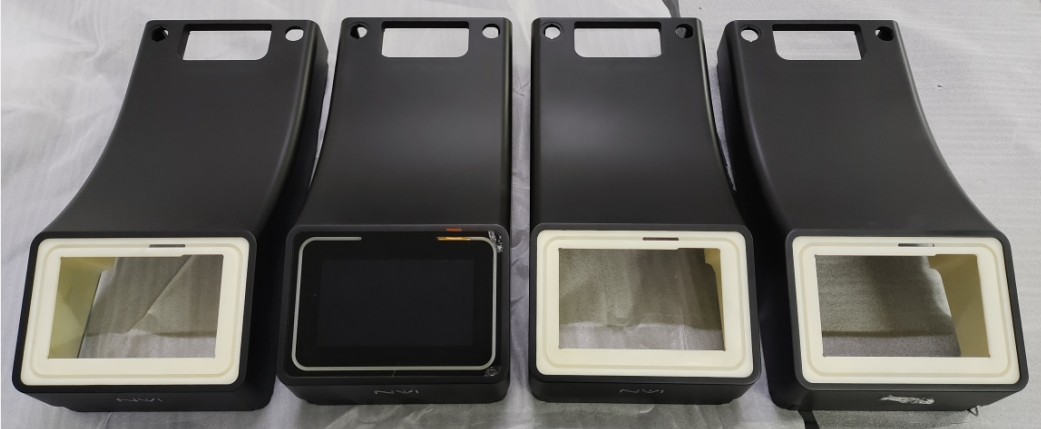

Our client is at the forefront of microbiological innovation, specializing in ultra-rapid microbiological testing machines that enable the accurate enumeration of bacteria and mold within minutes, transforming the way bacteria are detected and analyzed. Protolis has been entrusted with the manufacture of the protective enclosures that house these advanced testing machines. Our role is to ensure that the equipment operates in optimal conditions, protected by custom-engineered enclosures that meet stringent standards for functionality, durability, and hygiene.

Technological challenges

This project presented a set of challenges, combining complex geometry, precise assembly constraints, and demanding aesthetic requirements for a large medical-grade device:

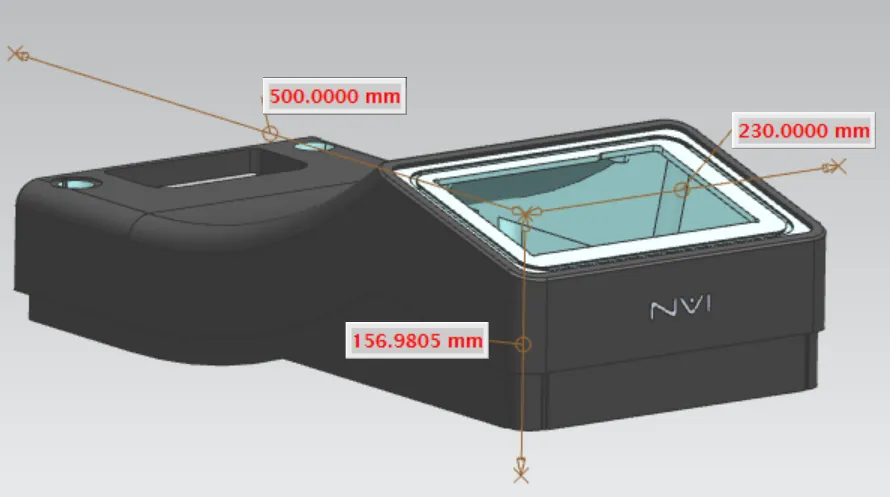

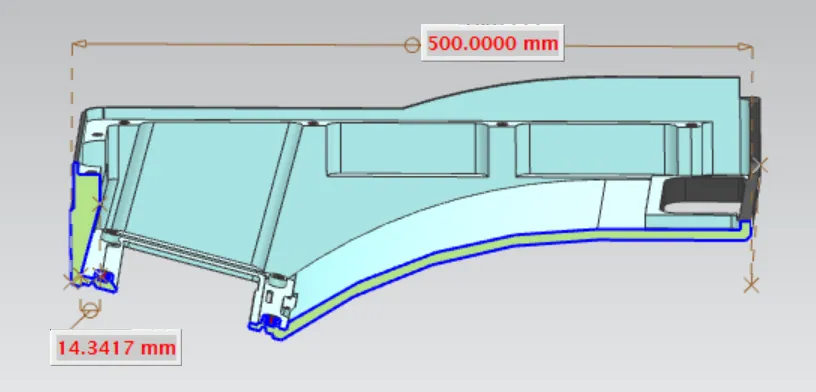

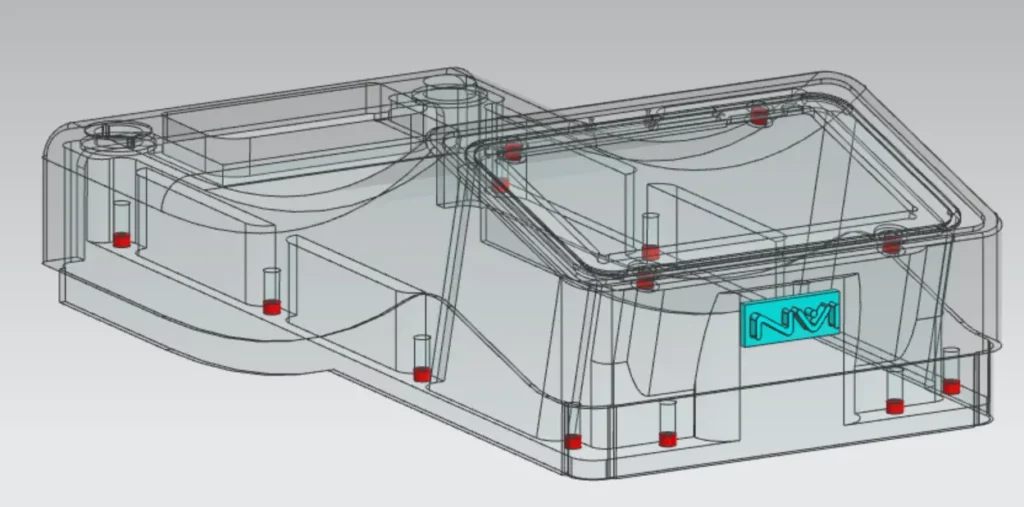

Large and complex enclosure design

The plastic enclosure is relatively large (500 mm x 230 mm) and features a complex internal structure with varying wall thicknesses and numerous undercuts.

Irregular internal undercuts

Many undercuts are irregular in shape and are essential to the product’s function and final assembly, making them impossible to simplify or remove.

Threaded inserts

Multiple types of threaded inserts are required, each needing to meet strict strength and alignment requirements for proper assembly.

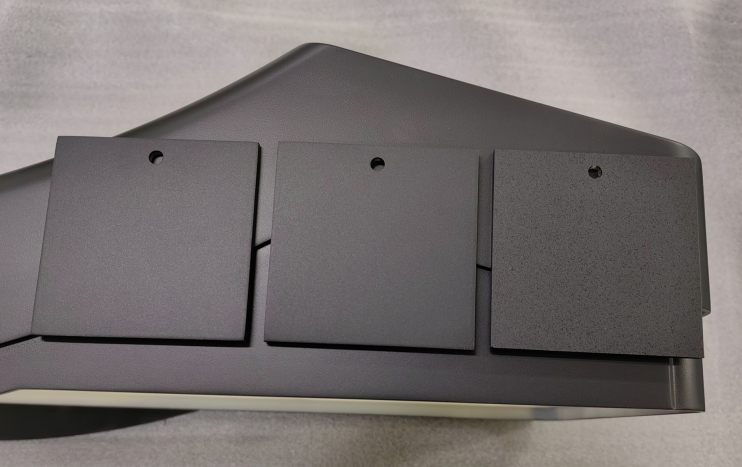

Surface finish and color matching

The enclosure must visually match a glossy-finished button, despite being painted with a sandblasted matte finish and without a specified Pantone or RAL color code.

Selective painting requirements

Specific areas of the enclosure must remain unpainted, requiring highly precise masking to ensure sharp, clean edges between painted and unpainted surfaces.

Wall thickness and risk of deformation

A thin-wall section near the display interface presents a risk of deformation during assembly and demands careful handling.

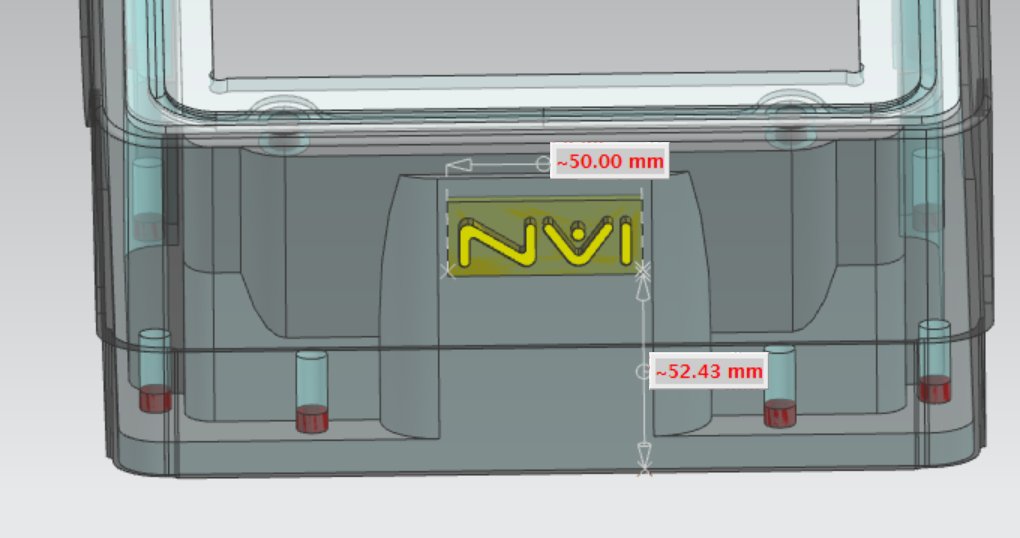

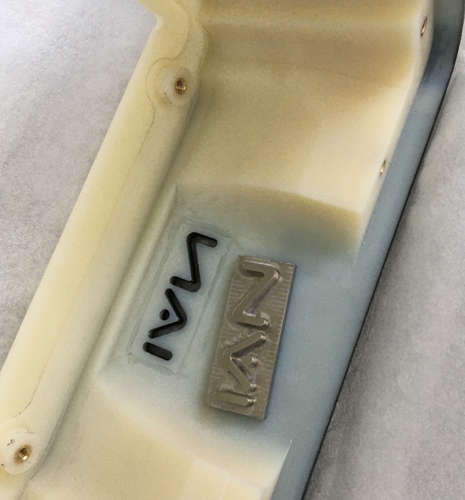

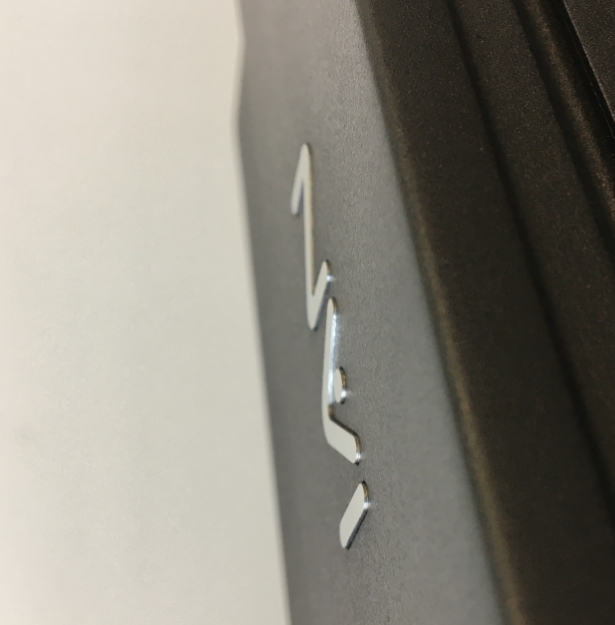

Logo integration

A separately manufactured, CNC mirror-polished logo must be securely integrated into the housing without risk of detachment over time.

Solutions provided by Protolis

To address these complex challenges, Protolis applied a combination of advanced manufacturing techniques:

Solution for complex geometry

We used CNC machining in combination with a multi-part assembly approach to achieve the complex geometry of the plastic medical enclosure (multiple undercuts and intricate internal features). We divided the design into several smaller components, which were individually machined and then precisely bonded together to recreate the whole geometry while maintaining tight tolerances.

Precision insert placement

Robust assembly procedures ensure all threaded inserts are positioned accurately and meet the required mechanical strength.

Iterative color matching process

Multiple paint tests and visual assessments were conducted to match the glossy component without official color references, achieving an excellent visual match.

High-precision masking

Specialized masking techniques protect unpainted areas during painting, maintaining clean transitions and a high-quality finish.

Deformation control measures

Quality control processes and production adjustments prevent deformation in the thin-walled display area, ensuring a precise fit.

Secure logo mounting via interference fit

A custom interference-fit design securely holds the CNC-polished logo in place, eliminating the need for adhesives and combining durability with a refined appearance.

Conclusion

Protolis is well placed to solve complex engineering challenges with precision and efficiency. From managing intricate geometries to achieving strict aesthetic and assembly requirements, we deliver high-quality medical enclosure solutions tailored to advanced technologies. Our expertise in design, manufacturing, and finishing ensures both functionality and visual consistency, and we work closely with clients and adapt to their various demands. Contact us now!