| Product | Acrylic Medical Flow Nozzle |

| Technology | CNC |

| Material | PMMA |

| Finish | Fine polishing |

| Timeline | 27 days |

| Quantity | 2 sets |

About our client

Our client is a pioneering medical technology company dedicated to advancing radiotherapy through innovative high-power electron LINACs solutions. With their expertise in project management, R&D, industrialization and manufacturing, they deliver groundbreaking cancer treatment technologies to improve cure rates, reduce treatment costs, and enable more efficient, patient-centered cancer care worldwide.

Key challenges and solutions

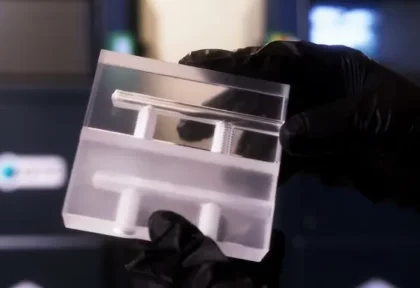

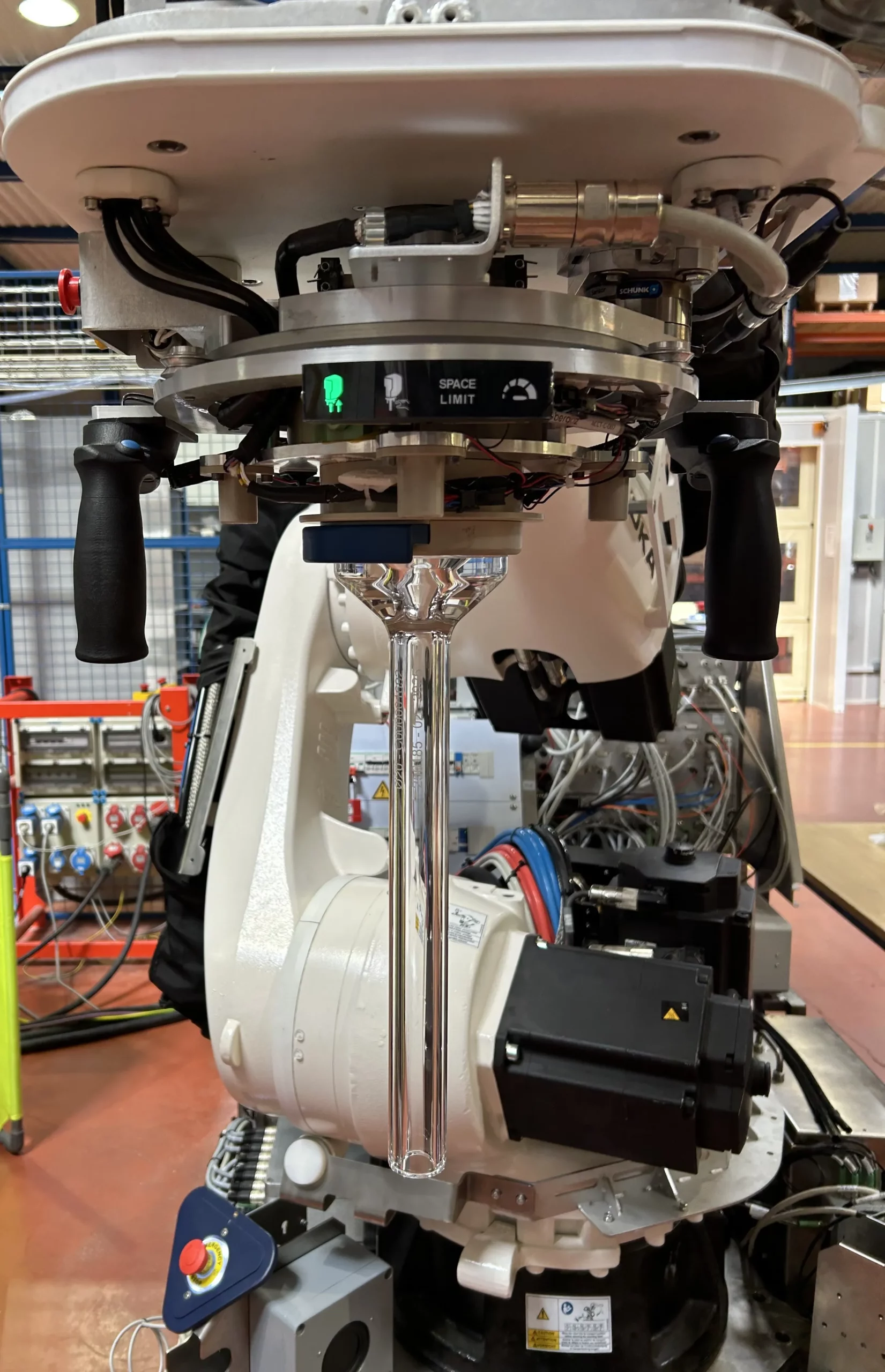

Tight geometry in fragile material

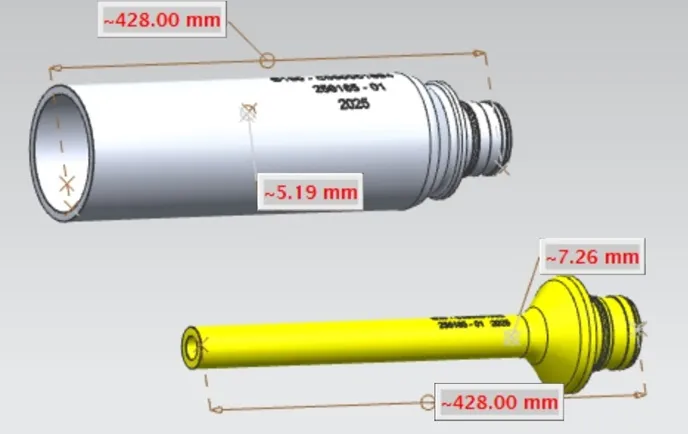

When we examined the first applicator, the geometry alone hinted at potential difficulties. With an inner diameter of only 20 mm and a length stretching to 428 mm, the proportions were far from forgiving. Add to that the fact it was made from a relatively brittle acrylic, and you have a part that, in most cases, would be prone to internal stresses and fractures during CNC machining or even careful handling. There’s very little margin for error.

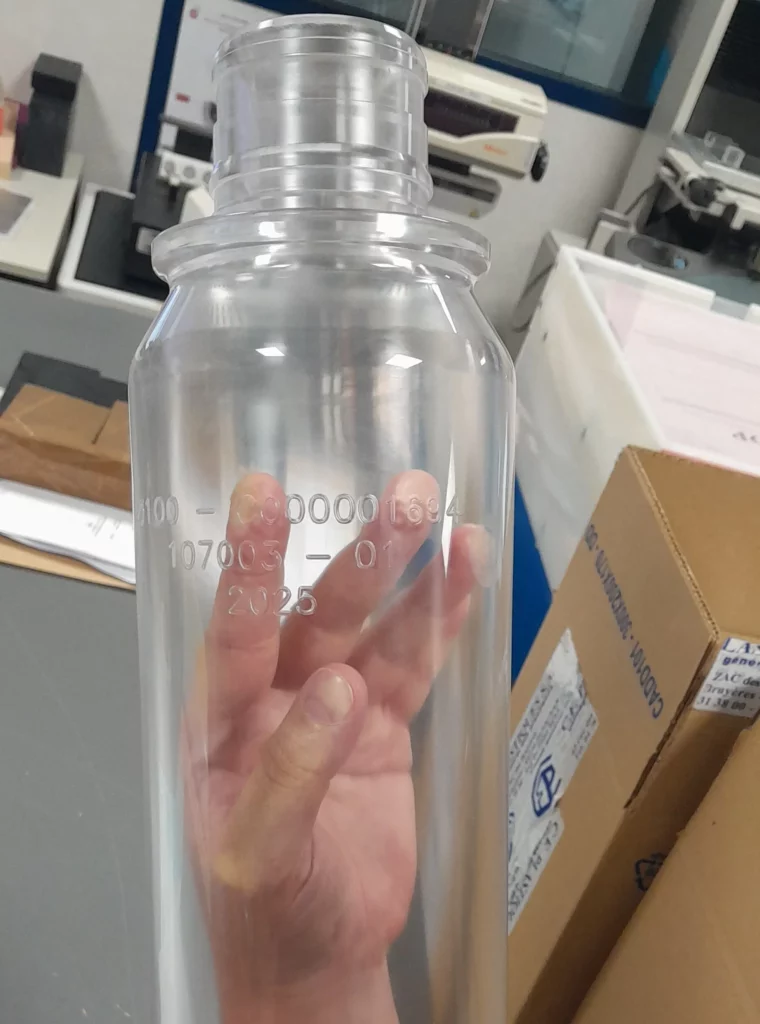

Polishing through complex stepped necks

Both applicators also came with stepped necks, which at first glance may seem like a minor design detail but quickly become a headache when it comes to mirror polishing. Narrow transitions limit tool access, making it hard to maintain a consistent finish from one section to the next. The customer’s original sample had a hazy, near-translucent look in these areas.

They were aiming for a true mirror-like clarity, something you’ll generally only achieve with refined polishing methods and a fair bit of patience. To achieve this, we used manual cloth wheel polishing, carefully working by hand to bring the surface to a true mirror finish. We took our mirror polishing process right through those restricted neck sections, and the end result was an even transparency across the entire surface, noticeably clearer than the original sample.

Learn more about polishing:

Four main types of Acrylic (PMMA) polishing process in Protolis

Marking in minimal space

The small outer diameter of the first applicator brought another practical problem. There simply wasn’t much real estate available for engraved markings. This meant the usual placement and spacing wouldn’t work without looking cramped or unbalanced. Our engineering team worked closely with the client to rethink the content, scale, and position of each marking so that, visually, everything still read cleanly and evenly.

Precision tolerances for accurate assembly

Finally, the assembly tolerances between the two applicators were tight, even tighter than what you’d typically see in similar components. Applicator 1 had to hold perpendicularity within 0.05 mm, while Applicator 2 needed concentricity within 0.1 mm. Those figures don’t leave much breathing room, so every step of the machining and inspection process had to be watched closely to ensure the final parts would align perfectly once assembled.

Results

We delivered both applicators to the highest standards, exceeding the client’s expectations. Mirror polishing achieved flawless, mirror-like transparency, while redesigned markings fit perfectly within the limited space for a clean, balanced look. Strict adherence to tight tolerances ensured a perfect fit and smooth assembly, combining exceptional visual quality with precision engineering.