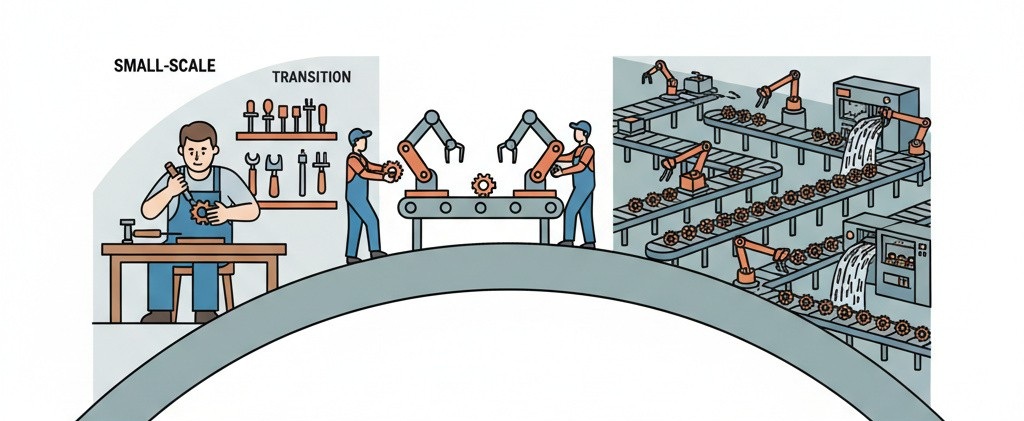

Bridge production — also known as a transition phase or pilot run — is an intermediate manufacturing step between prototyping and full-scale production.

It enables companies to produce final-quality parts in limited quantities using fast and flexible processes such as CNC machining, vacuum casting, or prototype tooling, while the final production tools (high-volume steel molds, automated lines, etc.) are still being manufactured and validated.

This approach reduces time-to-market, de-risks industrialization, and allows design and performance validation before committing to major production investments.

When is Bridge Production needed?

Bridge production applies to several real-world scenarios:

- Pilot runs and pre-series builds — to validate assembly, performance, or certifications before ramping up.

- Market testing — when companies want to test demand or product functionality before committing to expensive molds.

- Production delays — when mass-production tooling is not yet ready, but customer deliveries must start.

- After-sales or legacy parts — when the original molds are no longer available, yet parts are still required in small batches.

- Transition phases — when a design is nearly mature, but further feedback is still expected from users or regulators.

In short, bridge production ensures continuity, flexibility, and speed in uncertain or fast-moving development environments.

Advantages of Bridge Production

- Accelerated time-to-market – Start delivering to customers while waiting for final tooling.

- Risk reduction – Validate materials, tolerances, and assembly before mass production.

- Design flexibility – Make adjustments easily without re-cutting steel molds.

- Better cash flow – Spread investment over time instead of committing upfront to full tooling.

- Pre-production certification – Produce parts with final materials and processes for quality and regulatory testing.

Challenges and limitations

While bridge production brings flexibility, it’s not without challenges:

- Design compatibility – Parts made with flexible tooling (e.g., vacuum casting or soft molds) may not perfectly match the constraints of mass production.

It’s critical to ensure DFM (Design for Manufacturing) compatibility from the start. - Higher unit cost – Because tooling is less automated and production volumes are low; the cost per part is higher than in mass production.

A strategic analysis is needed to decide when to switch from bridge production to full manufacturing. - Quality variation – Low-volume methods can show slightly less stability and repeatability.

It’s important to apply additional quality control to bridge-produced parts.

Technologies commonly used for Bridge Production

| Technology | Typical Quantity | Materials | Notes |

| Vacuum Casting | 10–100 pcs | PU, ABS-like resins | No tooling cost, good for functional testing |

| CNC Machining | 1–100 pcs | Plastics & metals | High precision, real materials |

| Rapid Injection Molding | 100–2,000 pcs | Plastics, silicones | Aluminum or prototype steel molds, ideal for pre-series |

| 3D Printing (SLS, SLA, DMLS) | 1–50 pcs | Plastics, resins, metals | Fast turnaround, but limited by size and mechanical properties |

How Protolis supports you through Bridge Production

At Protolis, bridge production is at the core of our expertise.

We offer all the key technologies under one roof to help you move efficiently from prototype to production: CNC machining, vacuum casting, rapid injection molding, and 3D printing.

In addition, we help mitigate the risks typically associated with this type of production. Our strong expertise in Design for Manufacturing (DFM) for full-scale processes allows us to provide the right technical guidance from the start. We also ensure that unit costs and quality levels remain fully optimized and tightly controlled throughout the bridge production phase.

Here are a few concrete examples from recent projects we delivered:

Case 1 — From prototype to full production

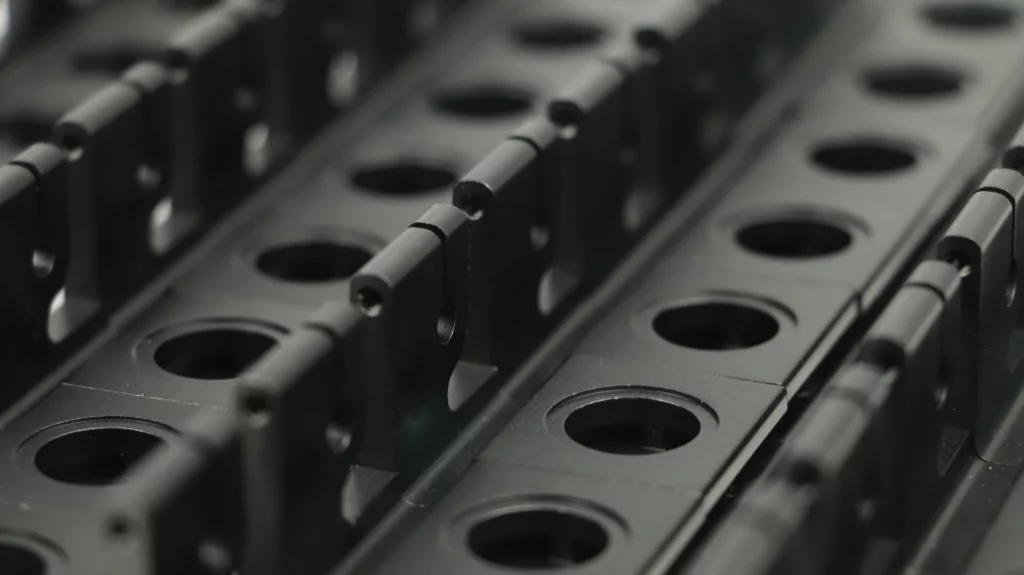

We supported this client throughout the entire product development process—from the first iterations to mass production. The project began with CNC-machined parts, enabling fast validation of design, geometry, and functionality.

Once the prototypes were approved, we produced a bridge batch using vacuum casting, a key pilot-production step to test assemblies, materials, and surface finish before investing in final tooling.

After full validation, we launched serial production using an injection mold designed to meet the required volumes and automotive-grade quality.

This phased approach helped reduce risks, accelerate time-to-market, and ensure a smooth transition from prototyping to industrial manufacturing.

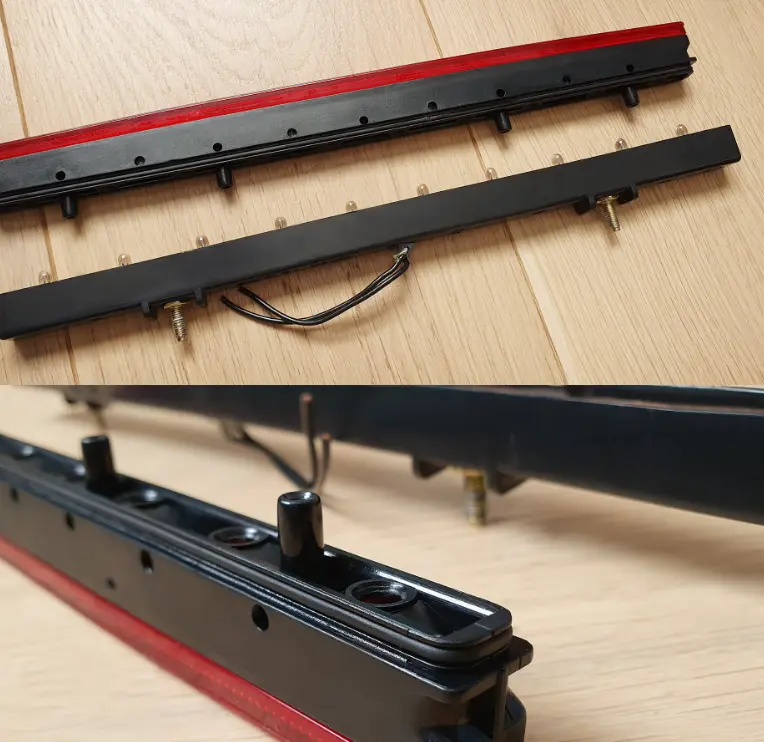

Case 2 — Niche market: automotive aftermarket series

In the automotive sector, aftermarket projects often require limited quantities while still meeting OEM-level quality and finish standards.

Our client needed to supply plastic components for the aftermarket, without clear visibility on long-term volumes, yet with the obligation to comply with materials and appearance specifications.

To meet this need, we manufactured the parts using prototype injection molds, ensuring consistency, repeatability, and final-product quality while limiting initial investment.

This solution provided reliable and compliant production tailored to a low-volume but demanding market.

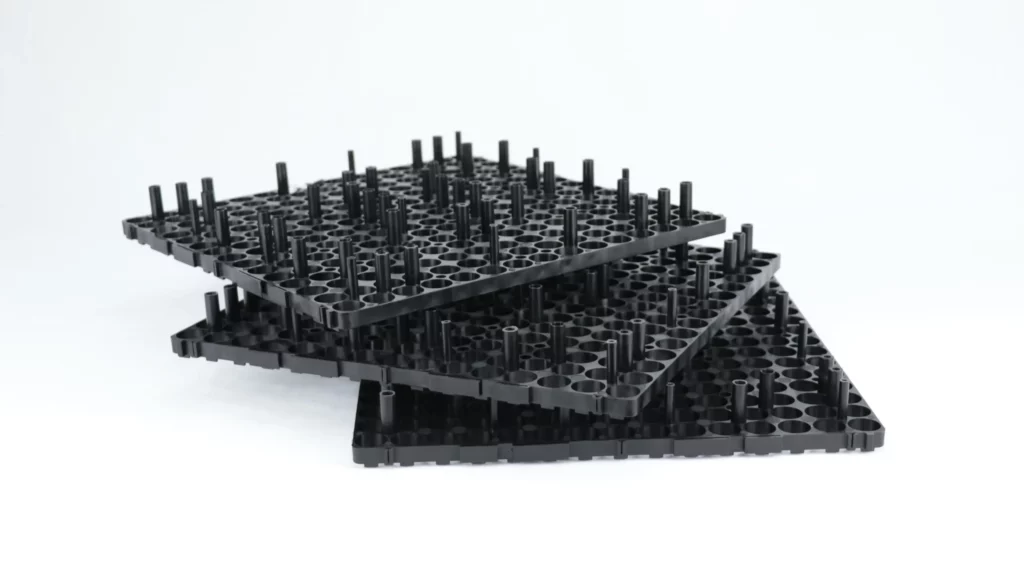

Case 3 — Small-batch production to validate a new market

This client’s goal was to validate market demand before committing to a high-volume investment.

They needed to test part mechanics, ergonomics, and user feedback while maintaining the option to iterate the design over several years.

We selected vacuum casting, ideally suited for small batches (approximately 25 parts) with realistic materials and high-quality finishes.

This method enabled short lead times, rapid field testing, and cost-controlled iteration prior to committing to mass-production tooling.

Thanks to this approach, the client successfully tested the product under real-world conditions while minimizing industrial and financial risks.

Conclusion

Bridge production bridges the gap between design and mass manufacturing.

It helps companies reduce risk, speed up market entry, and maintain flexibility, but only when managed strategically, with the right partner and processes.

Need Support with Your Bridge Production?

At Protolis, we help you evaluate, prototype, and industrialize your products with the right technologies at the right time.

Contact us today to discuss your next project.