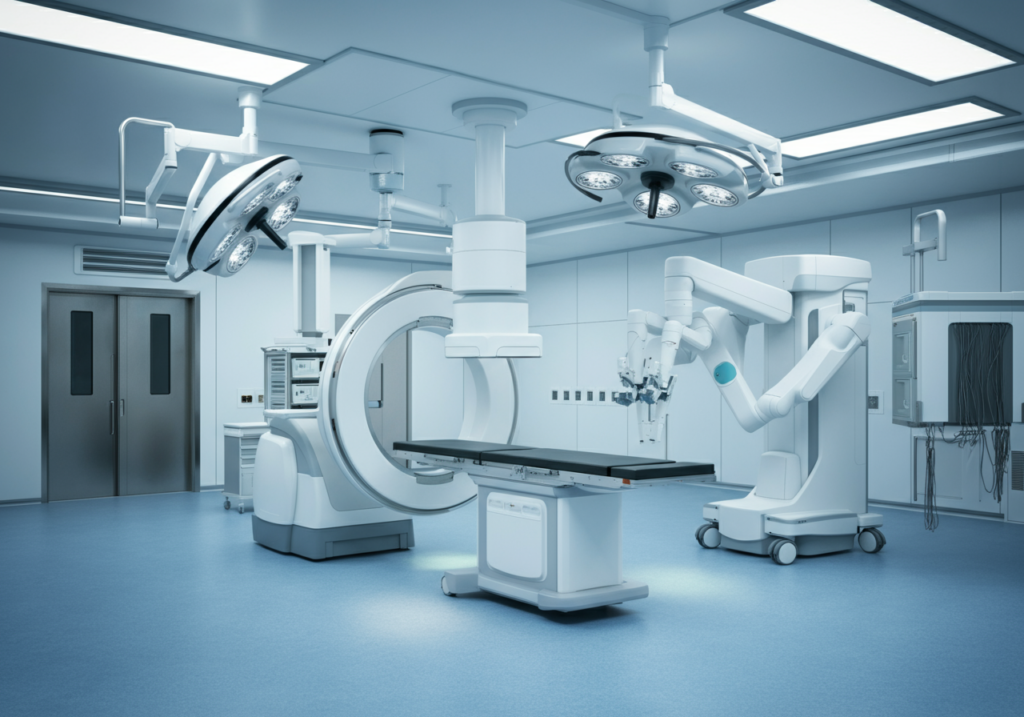

Medical plastics encompass a wide and complex field—from injection materials and single-use consumables to hospital equipment and, most notably, medical devices.

In this article, we focus exclusively on medical devices (and not on consumables such as syringes, bags, or tubings).

To understand their development context, it is important to recognize that each region applies its own regulatory standards: FDA in the United States, MDR in the European Union, and NMPA in China, among others.

For further information, visit our page on key medical regulations.

Manufacturing technologies for medical devices

Depending on the product development stage—prototype, pre-series, or mass production—several technologies may be used.

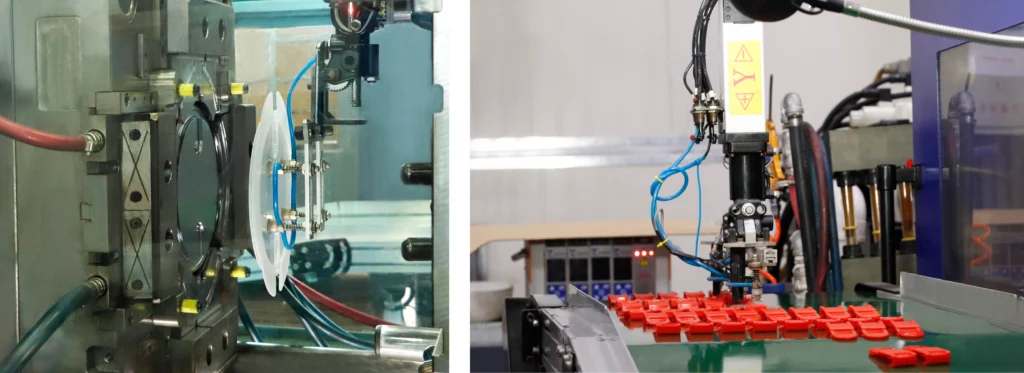

Plastic injection (thermoplastics)

Injection molding is the most common process for producing finalized medical devices. It is ideal for products that must meet strict requirements in terms of safety, reliability, and regulatory compliance.

The method supports a wide range of medical-grade thermoplastics, each capable of meeting the industry’s demanding standards:

- High mechanical strength for devices subject to repeated use

- Biocompatibility in accordance with ISO 10993

- Dimensional and chemical stability over time, even after repeated sterilization cycles (autoclave, gamma radiation, or ETO)

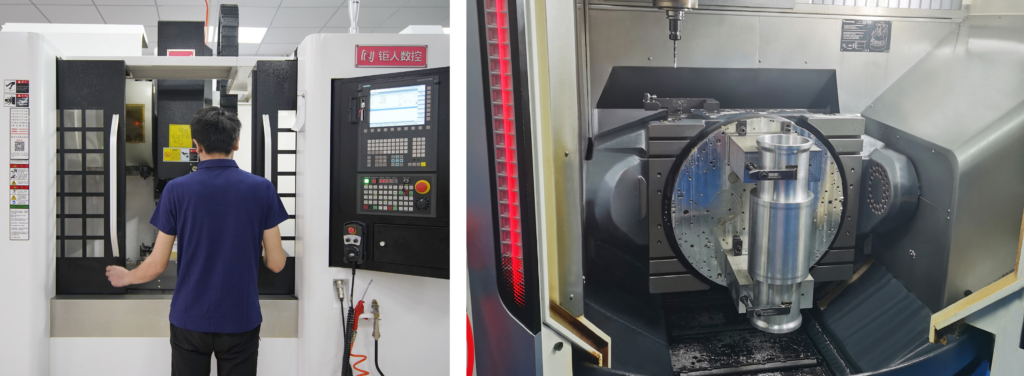

CNC machining of engineering plastics

CNC machining is particularly well-suited for functional prototypes, small series, and critical components that require tight tolerances or superior mechanical properties.

This process provides exceptional geometric precision enabling the production of complex parts in materials such as PC, PEI, PSU, or UHMW-PE.

Ideal for:

- Advanced prototyping using certified final materials

- Small technical batches when injection molding is not yet cost-effective

- Structural, high-performance parts needing rigidity and wear resistance

- Precision-fit assemblies and premium finishes for articulated mechanisms

CNC machining is a key step before industrialization, enabling faster product iterations while maintaining compliance with medical regulations and performance standards.

3D Printing (targeted applications)

3D printing is used for highly specific technical parts, most often during prototyping or for complex geometries that would be difficult to achieve with conventional processes.

Because material grades for additive manufacturing are often proprietary, this article focuses instead on thermoplastics commonly used in medical manufacturing.

Focus: Main Thermoplastics used in medical devices

| Material | Key Properties | Typical Applications |

| PC (Polycarbonate) | Excellent impact strength, dimensional stability, optical clarity, compatible with multiple sterilization methods (gamma, ETO, and steam, depending on grade). Highly resistant to mechanical shock in hospital environments | • Covers and optical windows for medical instruments• Protective shields• Diagnostic device housings• Medical connectors and electronic casings• Imaging system enclosures (see here a case study – PMB case study – ) |

| PEI (Polyetherimide—e.g., ULTEM™) | Outstanding heat resistance and rigidity, withstands multiple autoclave cycles, strong chemical resistance, ideal for sterile environments | • Handles for reusable surgical tools• High-temperature connectors• Structural parts for operating-room equipment• Internal mechanical supports |

| PSU / PPSU (Polysulfone / Polyphenylsulfone) | Excellent chemical resistance and thermal stability, tolerates repeated steam sterilization, transparent finish, and exhibits high resistance to cleaning agents | • Reusable infusion systems• Sterilization trays and racks• Ventilator and respirator components• Fluid-handling chambers |

| UHMW-PE | Extremely high wear resistance and low friction, proven biocompatibility, and excellent chemical and mechanical endurance under repeated load | • Orthopedic inserts (knee/hip)• Surgical guides• Bearings and sliding parts in medical robots• Articulated prosthesis components |

| PEEK (PEEK family) | High-performance polymer combining excellent mechanical and thermal strength, superior chemical resistance, dimensional stability, biocompatibility, and repeated sterilization capability (autoclave, gamma, ETO). Excellent strength-to-weight ratio | • Surgical implants (spinal, orthopedic)• Surgical instruments and ancillaries• Cutting guides• Dental implant components• High-performance structural parts for endoscopes and medical robots |

| Silicone (non-injected) | Highly biocompatible, flexible, chemically inert, and aging-resistant. Ideal for soft components or patient-contact parts requiring comfort and flexibility | • Breathing tips• Oxygen masks• Flexible seals and membranes• Patient-contact elements |

| LSR (Liquid Silicone Rubber) | High medical purity, excellent flexibility, precise molding capability, and strong thermal stability. Perfect for complex geometries and applications demanding hygiene and patient comfort | • Implantable LSR seals• Medical valves and membranes• Neonatal monitoring tips• Ergonomic soft parts |

Example of application with polycarbonate: see our PMB case study (radioprotection and medical imaging).

Alternative processes for low-volume production and validation

For low-volume or pre-industrial medical projects, certain resins are suitable for prototyping and validation:

- Vacuum casting

- RIM (Reaction Injection Molding)

Some formulations are certified for medical use and can be applied in pre-clinical testing phases.

Why material selection matters from the start

Material selection directly influences:

- Regulatory compliance and certification

- Sterilization method compatibility

- Product lifetime and durability

- Chemical resistance

- Tooling and production costs

- Time-to-market efficiency

Conclusion

Thermoplastics play a crucial role in the development of innovative, reliable, and regulation-compliant medical devices.

Depending on the product’s function, production volume, and lifecycle, injection molding, CNC machining, or technical resin processes may be the most suitable.

Selecting the right material grade from the start ensures quality, consistency, and scalability throughout production.

Need expert support?

Protolis supports your small-series manufacturing, providing material expertise and guidance on the most suitable technologies for your medical devices.

Contact us to discuss your project!