| Product | Racing car body |

| Technology | CNC plastic and metal, Sheetmetal, Welding |

| Material | ABS, Stainless steel,Aluminium |

| Finish | Painting, brushing, Anodization |

| Timeline | 3 Months |

| Quantity | 1 piece |

Our mission was to prototype the bodywork for the inaugural presentation of the car at auto shows. This involved creating the chassis and crafting all aesthetic body shell components needed for the impressive super car.

About our client

Our customer recently unveiled a supercar boasting exceptional characteristics. This supercar reflects the brand’s age and expertise in the automotive industry.

Our mission

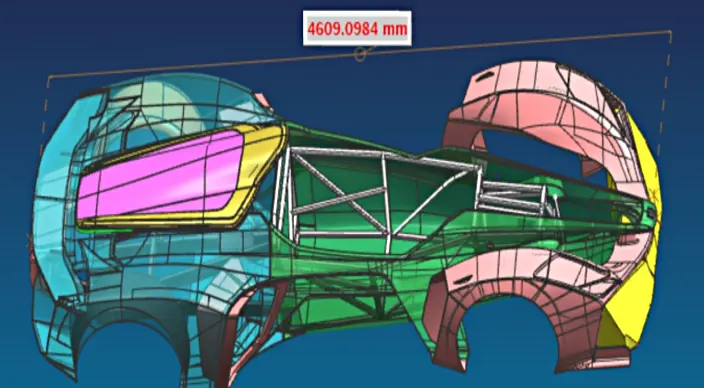

1. Creation of chassis by mechanical welding: to support the external aesthetic components, a complex metal structure was designed. A skilled welder worked on this substantial piece, utilizing cut metal, welding, and sheet metal. Precision was crucial to ensure the stability of the external aesthetic components.

2. Realization of the bodywork: the body frame parts were manufactured using a combination of CNC machining on ABS pieces, assembled, and then polished to create the illusion of a single piece. Preliminary painting was applied before the final finish. An aluminum hood was also created to complete the ensemble.

Technical challenges

The size and complexity of the racing car’s structure posed a significant challenge. The total length of the bodywork reaches nearly 5 meters, with a front part of 2.8 meters. The internal stainless-steel structure supports the entire assembly, requiring extreme precision in the assembly process. The design itself had flaws, necessitating optimization services to perfect the overall assembly.

Conclusion in photos

Images showcasing the concept car prototype are presented, highlighting the complexity of the structure, the intricacy of aesthetic details, and the quality of the finish.

We are proud to have contributed to this unique supercar, which combines exceptional performance, refined aesthetics, and the legacy of a renowned brand.