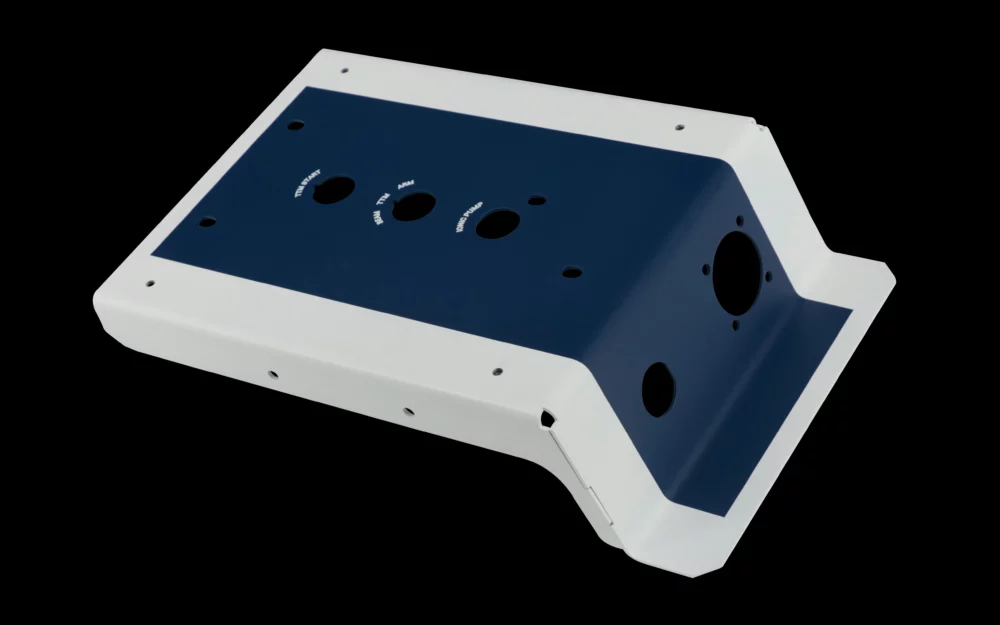

Custom medical device enclosures & housings for medical and life science equipment

Turn to Protolis for extensive expertise in prototyping and manufacturing custom medical device enclosures, with a strong emphasis on aesthetic excellence and functional precision. Our team produces plastic and metal housings for healthcare devices and wearables. From early prototypes to production-ready units, we meet the life-science industry’s most demanding standards.

High-quality medical equipment enclosures

With our precision manufacturing capabilities, we produce high-quality medical device enclosures engineered to protect internal components, enhance performance, and ensure lasting mechanical strength and environmental resistance. Certified to ISO 9001 and ISO 13485, Protolis guarantees that every enclosure meets the strictest medical safety and quality standards across a wide range of devices.

High-quality medical equipment enclosures

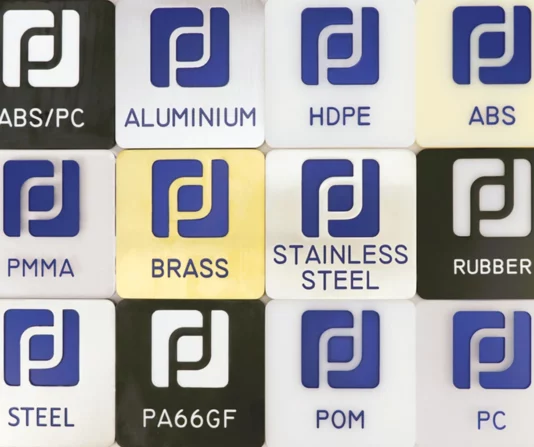

Materials for medical enclosures

We offer a wide selection of medical-grade plastics and metals tailored for enclosures that demand both performance and compliance. Our materials include flame-retardant ABS and PVC rated UL 94 V-0, antimicrobial and easy-to-clean surfaces, and advanced thermoplastics like polycarbonate for enhanced impact resistance.

Materials for medical enclosures

Our manufacturing methods for custom design enclosures

We offer vertically integrated turnkey solutions for the production of plastic and metal healthcare equipment housing, leveraging advanced manufacturing methods designed for cost efficiency and quick turnaround. Whether you need prototypes or small series production, our flexible approach ensures speed, quality, and reliability at every stage.

Vacuum casting and RIM

A cost-effective alternative for low-volume production, reaction injection molding offers custom casings with high detail.

Price:

Speed:

Design flexibility:

Manufacturability*:

CNC machining

Ideally suited for plastics such as ABS, PC, and PMMA, enabling high-precision fabrication of larger housing components.

Price:

Speed:

Design flexibility:

Manufacturability*:

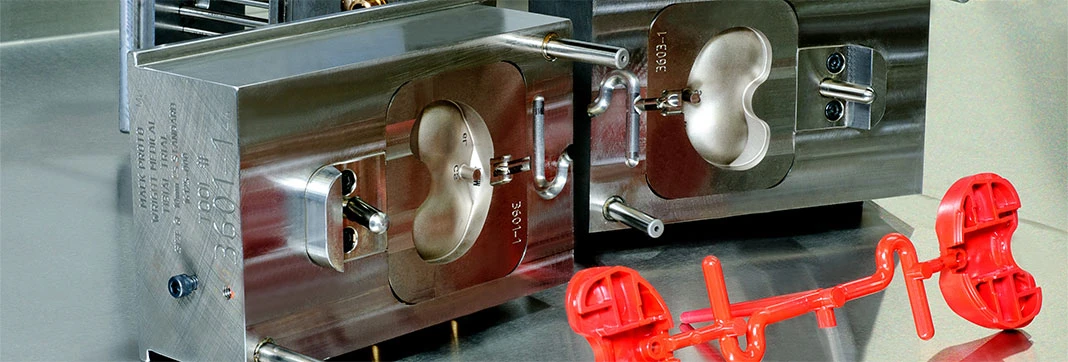

Rapid injection molding

Ideal for small to medium-sized devices with high-volume production, delivering high-quality, precise parts.

Price:

Speed:

Design flexibility:

Manufacturability*:

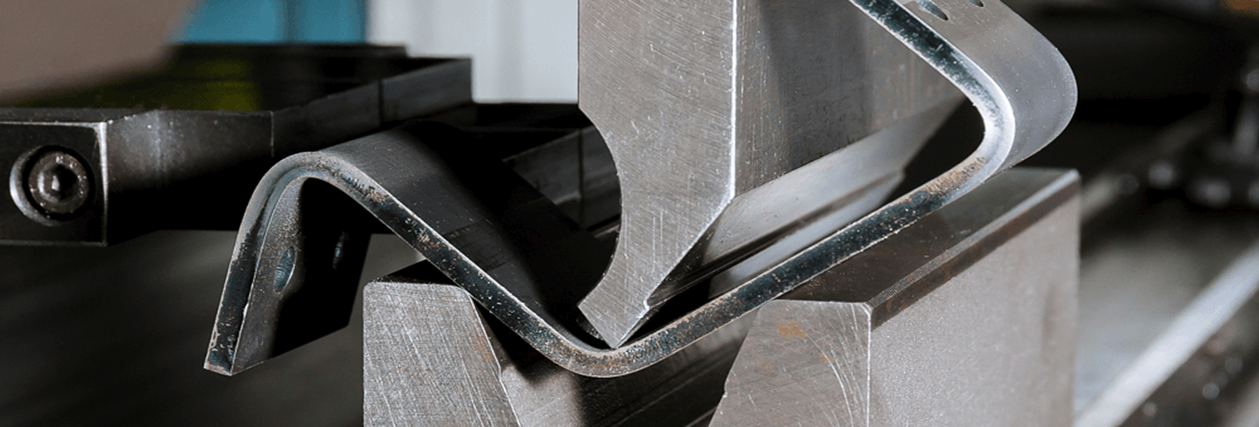

Metal sheet

The preferred solution for large stainless steel enclosures, providing strength, durability, and corrosion resistance.

Price:

Speed:

Design flexibility:

Manufacturability*:

Why choose Protolis for your medical enclosure needs?

Medical standards and compliance

Protolis follows the highest industry standards, complying with ISO 9001 & ISO 13485, FDA, and UL 94 requirements for medical-grade enclosures.

Medical standards and compliance

High-quality aesthetics and branding

We offer a wide range of finishes to give your medical equipment a professional and aesthetically refined appearance. Our custom finishing options include: paint coatings resistant to hospital-grade disinfectants, logo printing and branding solutions and copper shielding for EMI protection.

High-quality aesthetics and branding

The Protolis advantages

Protolis stands out in medical enclosure manufacturing, combining rapid prototyping and low-volume production to deliver exceptional results:

- Turnkey solutions: from design support to final assembly, all managed under one roof.

- Competitive pricing: outstanding value without compromising on quality.

- Precision and flexibility: challenge us — we are ready to adapt to your needs.

- Short lead times: production in as fast as 7 days for urgent medical projects.

The Protolis advantages

Rapid fabrication for complex medical components

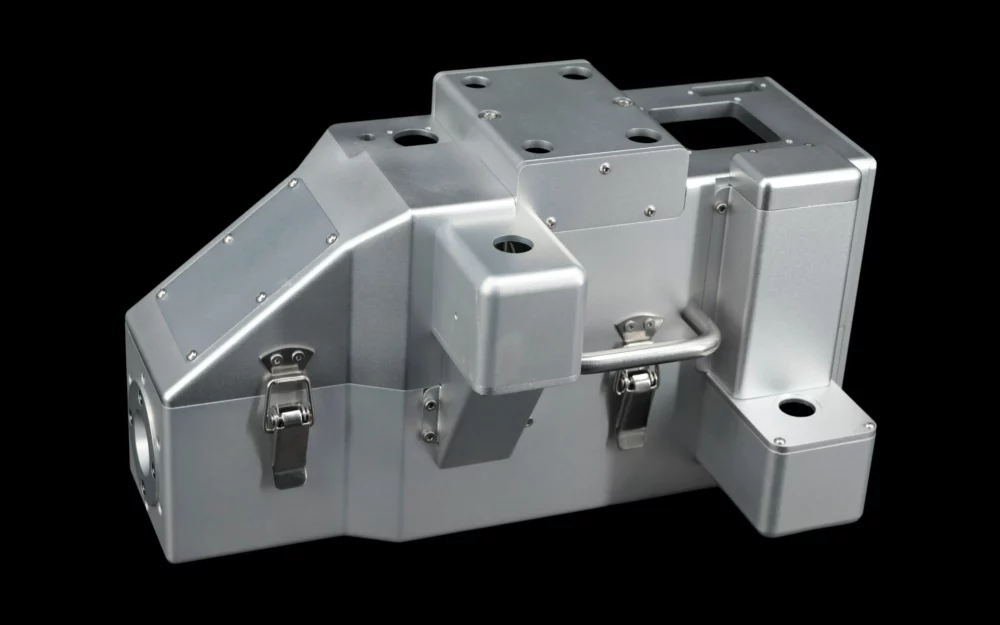

Protolis delivered a precision enclosure for a microbiological testing device in just 20 days, overcoming challenges in terms of shape, finish, and assembling requirements through expert prototyping and production know-how.

Explore this case study here and discover more real-world examples of our work here.

Rapid fabrication for complex medical components

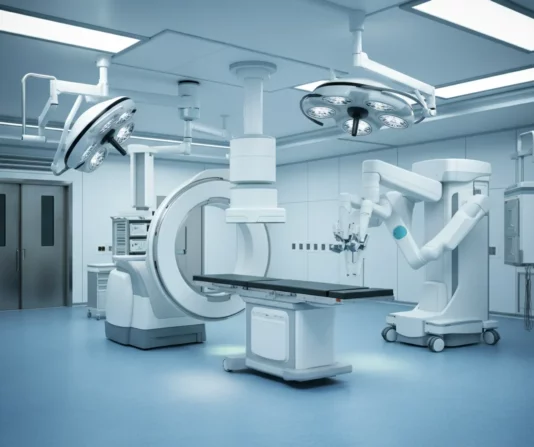

Medical housing and enclosure applications

Our custom enclosures are used in critical medical applications such as:

- Medical diagnostics equipment

- Medical testing equipment

- Medical laser equipment

- Laboratory equipment

- Medical rehabilitation devices

- Surgical robots

- Surgical laser enclosures

- Organ transport enclosures

- Monitor enclosures

- Endoscopy tower enclosures

- C-Arm

- O-Arm

- MRI scanner

- X-ray machines

- Wearable devices

FAQ

Which material is best for medical device enclosures?

Medical device enclosures are made from high-performance materials chosen for durability, sterilization resistance, and compliance with medical regulations.

- Polycarbonate (PC) is widely used for its impact resistance and transparency, ideal for imaging and diagnostic equipment.

- ABS is a lightweight, cost-effective option for electronic device housings.

- PEEK is preferred for its biocompatibility and high-temperature resistance, making it suitable for demanding applications.

- Medical-grade polypropylene (PP) is chosen for its chemical resistance and ease of sterilization.

- For stronger enclosures, stainless steel (316L) offers corrosion resistance, while aluminum provides lightweight strength with EMI shielding for electronic devices.

- Titanium is ideal for implantable or surgical enclosures due to its biocompatibility and durability.

All materials meet ISO 13485, IEC 60601, and FDA standards for medical applications. Let us help you choose the best material for your medical enclosure needs.

Can medical enclosures be manufactured in small batches?

Yes, we offer low-volume production using CNC machining, vacuum casting (or reaction injection molding), and injection molding for medical device prototyping and limited series.

How long does it take to manufacture a custom medical enclosure?

Lead times depend on design complexity, material choice, and production method, but we offer rapid prototyping and short-run production to meet tight deadlines.